WIDE RANGE OF SERVICES

Metal processing

Turning, milling, tooth milling, sheet bending works

Turning, milling, tooth milling, sheet bending works

“PMZ Denasmash” LLC has long and successfully provided a wide range of its services in the field of metalworking and engineering. We constantly cooperate with a large number of regular customers, successfully provide repair services and development of new equipment. But at the same time, we are also focused on finding new promising customers who do not yet know our products.

Our enterprise has all the possibilities to offer a variety of works in the field of mechanical engineering, repair and maintenance of construction machinery, various equipment, including the most complex and heaviest equipment.

“PMZ Denasmash” LLC allows even the most complex engineering dream to become a reality. Our experienced technologists, designers, engineers, machinists and other specialists know, understand and perform their work well. To get really high-quality technological equipment, its individual parts or complex repairs, you should contact us. Here you will find understanding in technical matters, we will gladly help you, explain and show you how to do it better. To get exactly what you need from the equipment, just call PMZ Denasmash LLC.

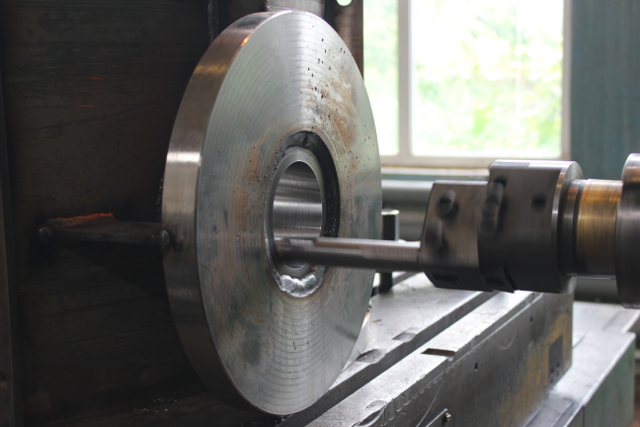

In the arsenal of the “PMZ Denasmash” LLC there are lathes capable of producing bodies of rotation with the smallest diameter – 2 mm, the largest possible diameter – 1000 mm. At the same time, the accuracy of processing is up to 2 hundredths of a millimeter, which allows you to meet all the needs of mechanical engineering, repair or small-scale production.

Our specialists can easily restore complex and expensive shafts, having previously soldered them, which is also produced by us. And this means that now you can order all works in one place – at PMZ Denasmash LLC. We will manufacture hammers, breakers and hydraulic breakers for your equipment. According to sketches, dimensions or drawings, we manufacture hammers for crushers to order.

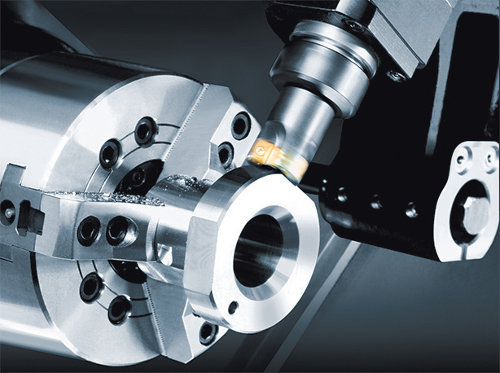

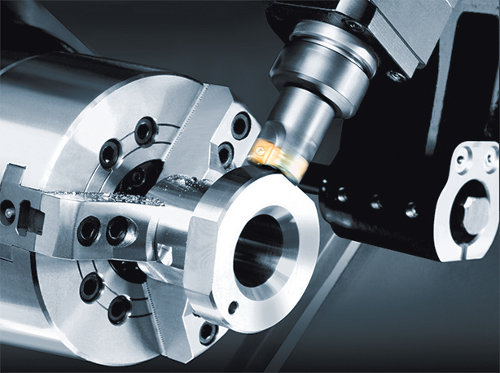

For the production of parts in large batches and with high accuracy, our company successfully uses CNC machines. They make it possible to manufacture parts of the most complex geometry and configuration. Experienced programmers of “PMZ Denasmash” LLC quickly compile complex programs for the manufacture of a wide variety of parts, in full compliance with technical regulations and requirements of GOSTs.

Thanks to CNC lathes, we are able to carry out a complete repair of internal combustion engines, with all its numerous components and components. CNC lathes allow the production of both the simplest bodies of rotation, with a tolerance of up to 0.005, and parts of a complex configuration with a diameter from 2 to 400 mm, with a maximum length of up to 600 mm. For the production of parts in large batches and with high accuracy, our company successfully uses machines with CNC They make it possible to manufacture parts of the most complex geometry and configuration. Experienced programmers of “PMZ Denasmash” LLC quickly compile complex programs for the manufacture of a wide variety of parts, in full compliance with technical regulations and requirements of GOSTs.

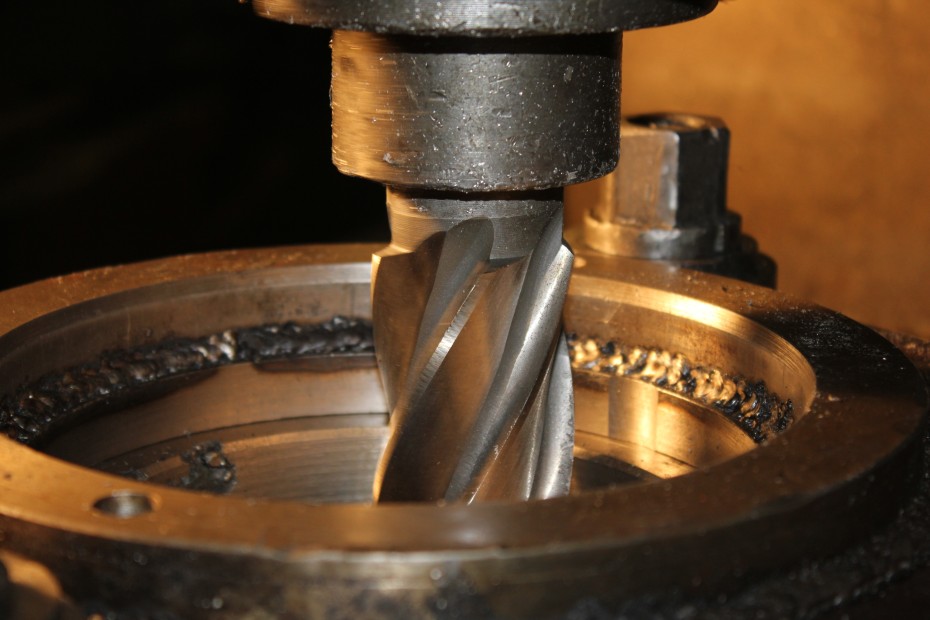

Milling works allow you to produce parts of absolutely any configuration, any complexity and size. At PMZ Denasmash LLC, you can order and manufacture various machine parts and assemblies.

CNC milling machines are used for a large number of identical parts of a complex configuration with many grooves, recesses and ledges with technological holes, grooves and other elements. Geometric dimensions 400/500/600 with an accuracy of 0.005 millimeters.

This type of work is used for the production of large and complex parts, mainly with cylindrical holes. Geometric parameters: 320 x 560, hole diameters: Ø 3 – 125. Processing accuracy – 0.02.

Due to its accuracy and minimal tolerances, coordinate boring works allow to perform such technological operations as the repair of internal combustion engines, and many other more complex and even more accurate ones.

This type of work will allow you to perform the most complex operations with an accuracy of up to 0.05 mm, while it becomes possible to repair internal combustion engines. After all, its numerous holes require the highest precision and cleanliness of processing.

A universal horizontal boring machine with a huge table makes it possible to place and process parts weighing up to 3 tons and measuring 2000 by 1000 mm. The diameter of the treated holes is from 3 to 600 mm.

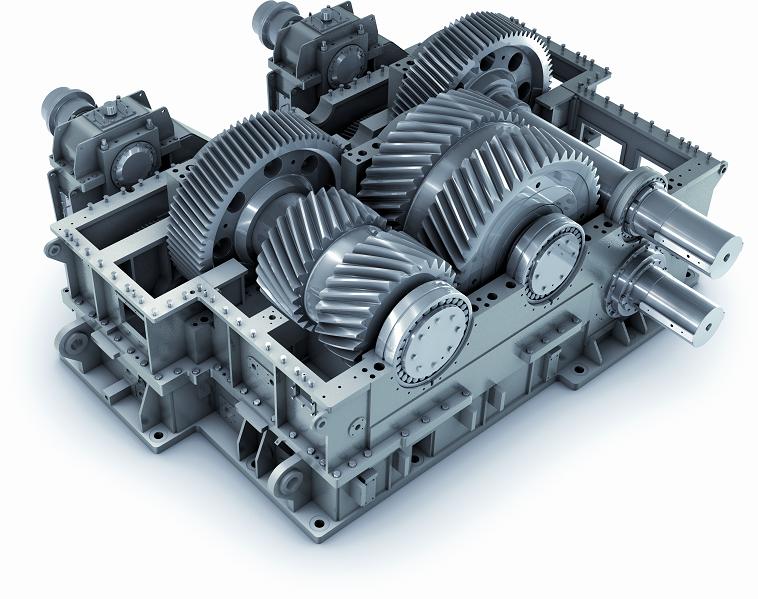

A universal gear milling machine and several of its modifications will allow you to produce gears of various sizes, with a module from 1 to 10. Cylindrical spur gears, cylindrical helical gears and worm wheels of any configuration and model.

With the help of a gear milling machine, PMZ Denasmash LLC successfully repairs gearboxes, gearmotors, completely restores gears and cuts new ones.

Universal and incredibly powerful sheet bending will allow you to produce parts up to 4000 mm long, including sheets or pipes of any configuration permitted by the laws of physics.

The creation of parts and assemblies takes place by processing blanks of a flat shape according to the specified parameters. The main advantage of the method is the absence of seams and no welding. The resulting products are distinguished by high performance indicators and are less prone to corrosion formations.

CHOOSE THE BEST AND BE SURE OF THE RESULT

TELEPHONE NUMBER

MAILING ADDRESS

Ukraine, 36007, Poltava, Zavodska Street, 3