Granulation of biomass

WANT TO BE CONFIDENT IN THE PERFORMANCE OF YOUR EQUIPMENT - BUY GRANULATORS FROM US!

Granulation of biomass

A STRONG AND RELIABLE PARTNER

| Press granulator | ||

| Productivity | kg/h | 800-1200 |

| Gearbox type | – | Belt, 2-х sd |

| Matrix rotation frequency | rev/min | 150 |

| Matrix type | – | OGM-1,5 |

| Power of the main engine | kW | 90 |

| Mixer drive power | kW | 3,0 |

| Overall dimensions in a horizontal and straight position, no more than: – length – width – height | mm mm mm | 2140 1771 1919 |

| Маss | kg | 2850 |

| Belt conveyor inclined 7.2 | ||

| Type of traction element | – | PVC tape |

| The width of the traction element | mm | 500 |

| The frequency of rotation of the drums | rev/min | 56 |

| Diameter of drums | mm | 159 |

| Length of transportation | m | 7,2 |

| Performance, to say the least | kg/h | 1500 |

| Drive power | kW | 1,5 |

| Маss | kg | 420 |

The granulator is the main part of the equipment, designed for obtaining pellets from biomass by pressing it with pressing rollers through the radial holes of the ring matrix.

THE WORKING PRINCIPLE OF THE PRESS GRANULATOR IS AS FOLLOWS:

The product is fed evenly into the mixer, the main task of which is continuous mixing and moistening of raw materials, as well as forced feeding of the mixture into the pressing chamber of the granulator.

Structurally, the mixer is a horizontal cylinder with inlet and outlet nozzles, inside which a paddle mixer rotates in two bearings, which is driven by a V-belt transmission from an electric motor.

The prepared mixture enters the pressing chamber between a rotating ring matrix with a horizontal axis of rotation and two rollers rotating inside it on fixed axes. The matrix is driven by an electric motor. At the same time, due to friction, the pressing rollers rotate. The torque from the electric motor shaft through the two-stage V-belt drive rotates the faceplate shaft with the matrix. At the same time, the pressing rollers rotate from the contact with the raw material located on the inner surface of the matrix. The raw material fed into the pressing chamber is pulled between the rotating matrix and the pressing rollers and is pushed into the radial holes (dillers) of the matrix, where granules are formed under the action of high pressure. The granules squeezed out of the die matrix break off. The broken pellets from the cover with a presser are sent further along the technological process.

Safety shear fingers are provided in the design. In the case of overloading or jamming of the matrix fixed on the faceplate with rollers (when a foreign body hits between them), the increased force cuts off the safety fingers, and the normally stationary axis together with the flange rotates.

The press granulator is rigidly attached (with an anchor or other rigid connection) in a certain place of the room to the base (floor of the room, concrete base, metal structures, etc.).

Granulators are used for the production of fuel, fodder or other types of pellets, which are small cylinders of a given diameter (from 3 to 10 mm) and length (5-50 mm). The equipment can be used in domestic conditions, on farms and industrial productions. Granulation allows you to prepare compound feed with an optimal formulation, ensures the introduction of liquid food additives and medicines, which significantly reduces the possibility of bacteria entering the feed, increases the degree of digestibility of products and, as a result, guarantees faster fattening of animals, a reduction in the amount of waste, and also reduces losses during storage and transportation of compound feed .

With the help of granulators, fuel pellets are also produced, which are obtained by processing wood waste and agricultural waste. Fuel pellets (pellets) have a higher energy density than firewood, less ash after combustion, and are more convenient to use and store.

Various materials can be granulated. However, you should know that for each raw material it is necessary to develop its own production technology, 3 which will differ depending on many parameters: composition, humidity, fat content, temperature, storage method

WORKING PRINCIPLE

The principle of operation of the granulator is to squeeze the raw material through the holes (spindles) of the matrix with rollers. The basis of the process is the compression of finely divided material in the gap between the pressing rolls and the surface of the matrix. The material is compressed until, under the influence of heat, moisture, and pressure, it acquires thermoplastic properties and is pushed through the dies of the matrix. The extruded granules are broken off by a knife and fall down onto the ejector disc. Further, through the tray, they are thrown out of the granulator with a temperature of 50-70 ˚C.

MAIN TECHNICAL PARAMETERS

| Parameter name | Unit of measurement | Value |

| 1. Type of granulator | – | With a rotating matrix |

| 2. Drive type | – | Electric motor |

| 3. The number of revolutions of the matrix | rev/min | 180-280 |

| 4. Productivity | kg/h | 250-500 |

| 5. Installed capacity | kW | 15 |

| Overall dimensions: length, width, height | mm mm mm | 2140 1771 1919 |

| 7. Маss | kg | 410 |

Generalized requirements for raw materials

- The optimal humidity is about 15%

- The raw material fraction should be 1 mm smaller than the diameter of the holes in the matrix

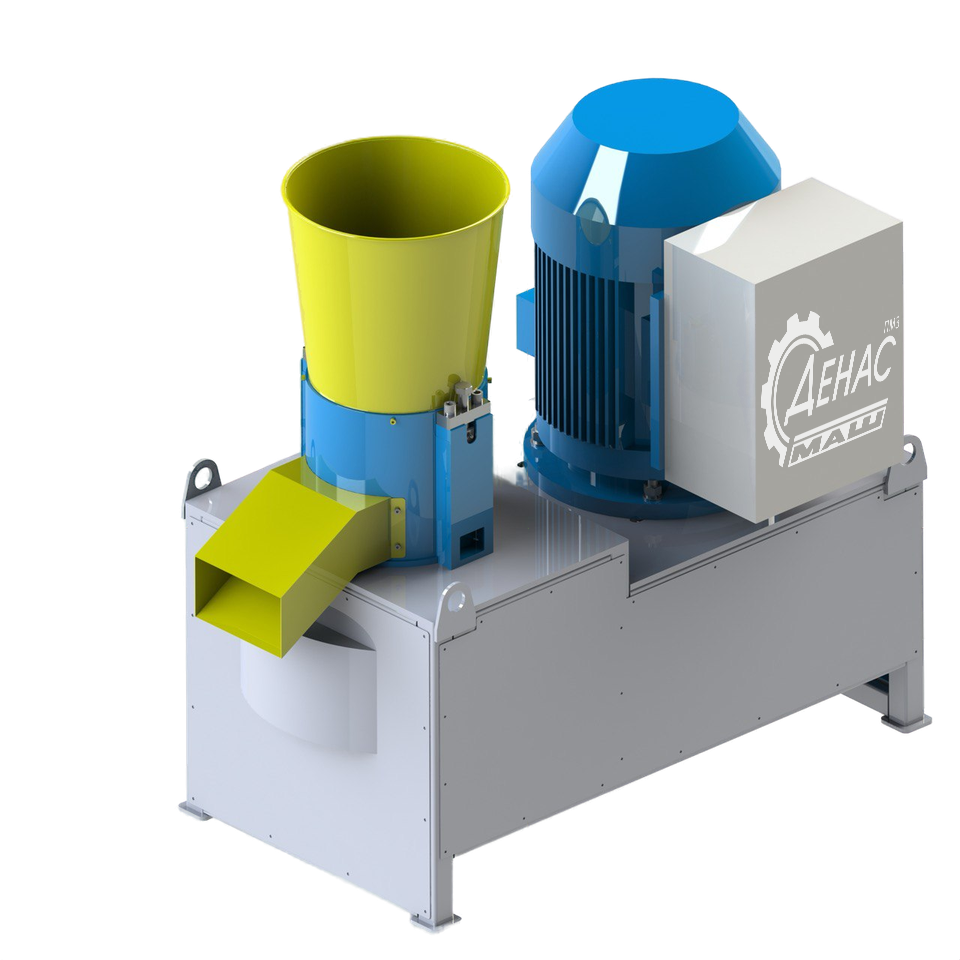

OGM-1.5M granulator

The OGM-1.5M granulator is a modernized (reinforced construction of nodes, high productivity), specially designed granulator for the field of bioenergy, which has proven itself for many years of trouble-free operation. The press granulator is designed for the production of pellets from various types of raw materials: wood waste, straw, peat, cereal husks, sunflower husks, bird droppings, etc. The equipment produces high-quality and durable pellets.

Productivity – 1-1.3 t/h (depending on humidity, fraction, density and type of raw material).

Granulator B6DGV-M

The B6DGV-M granulator is an improved model of the B6DGV granulator with increased productivity and reinforced construction nodes. Reliability and performance indicators have become even better! The equipment is capable of granulating any raw material: wood waste, straw, peat, cereal husks, sunflower husks, etc.

The granulator has proven itself well in the market of biofuel producers. The machine produces high-quality and durable pellets, which you can see by visiting one of our plants.

Productivity – 1.5-2.2 t/h (depends on humidity, fraction, density and type of raw material).

Granulation line

To date, “PMZ Denasmash” LLC provides a full range of services for the organization and manufacture of a complex for biomass processing, starting from the development and ending with the manufacture of all equipment included in the granulation line, commissioning, commissioning, training of personnel, service and post-warranty service .

Productivity on husk seeds, wood waste – from 1 t/h;

Productivity of compound feed – from 1 t/h.

Spare parts, details for granulators OGM-1.5 and B6DGV

The presence of specialists and equipment at our factory allows us to completely make a part from a blank to a finished spare part – we have a closed production cycle. At the same time, we control the quality at every stage of production and produce in a short time.

We work without intermediaries, which allows us to make a low price and at the same time produce high-quality products: high-speed gear shaft (lower shaft), intermediate shaft – gear (middle shaft), middle shaft gear (intermediate shaft), main low-speed shaft (plane washer) , matrix fastening clamps, rollers, bushings, splined shaft, plates (diamonds), large (low-speed) gear, coupling, matrices for various types of raw materials.

SUBMIT A REQUEST

CHOOSE THE BEST AND BE SURE OF THE RESULT

CONTACT US IN A CONVENIENT WAY

TELEPHONE NUMBER

MAILING ADDRESS

Ukraine, 36007, Poltava, Zavodska Street, 3