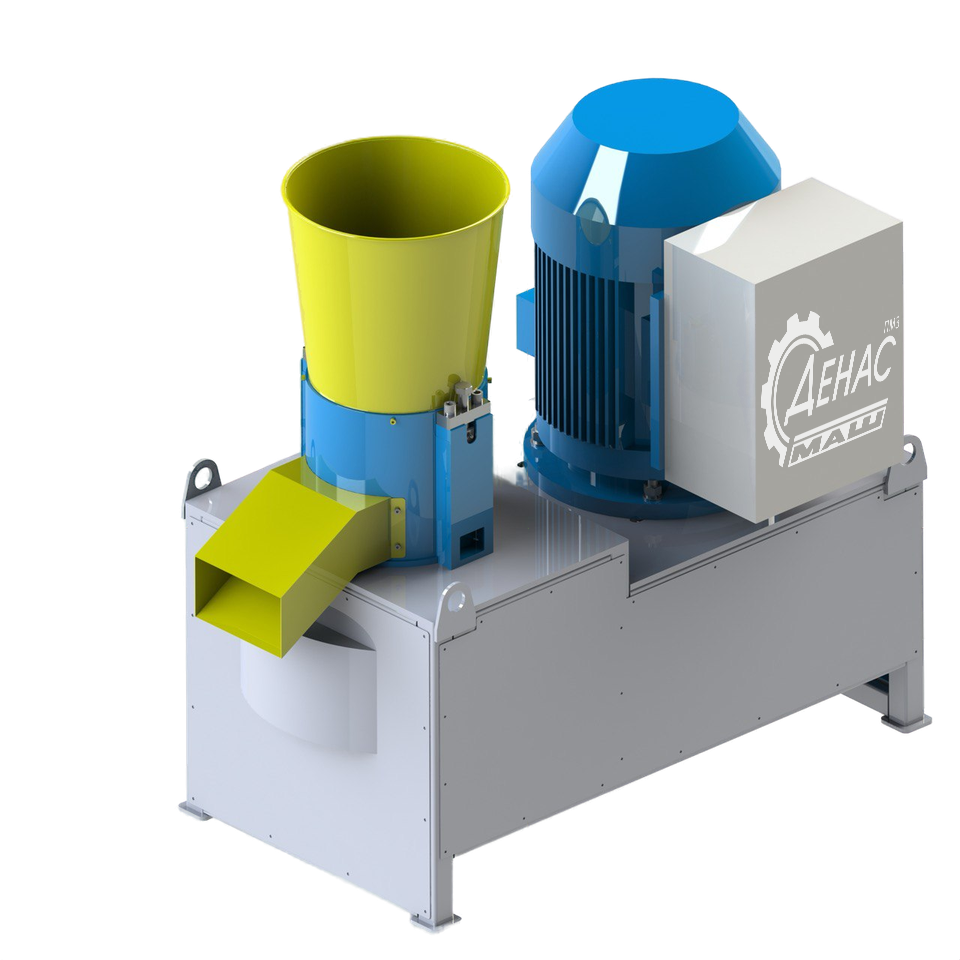

Granulator Sonic

They allow the mechanism to function even under the highest loads

Make an orderThey allow the mechanism to function even under the highest loads

Make an order

Granulators are used for the production of fuel, fodder or other types of pellets, which are small cylinders of a given diameter (from 3 to 10 mm) and length (5-50 mm). The equipment can be used in domestic conditions, on farms and industrial productions. Granulation allows you to prepare compound feed with an optimal formulation, ensures the introduction of liquid food additives and medicines, which significantly reduces the possibility of bacteria entering the feed, increases the degree of digestibility of products and, as a result, guarantees faster fattening of animals, a reduction in the amount of waste, and also reduces losses during storage and transportation of compound feed .

With the help of granulators, fuel pellets are also produced, which are obtained by processing wood waste and agricultural waste. Fuel pellets (pellets) have a higher energy density than firewood, less ash after combustion, and are more convenient to use and store.

Various materials can be granulated. However, you should know that for each raw material it is necessary to develop its own production technology, 3 which will differ depending on many parameters: composition, humidity, fat content, temperature, storage method

The principle of operation of the granulator is to squeeze the raw material through the holes (spindles) of the matrix with rollers. The basis of the process is the compression of finely divided material in the gap between the pressing rolls and the surface of the matrix. The material is compressed until, under the influence of heat, moisture, and pressure, it acquires thermoplastic properties and is pushed through the dies of the matrix. The extruded granules are broken off by a knife and fall down onto the ejector disc. Further, through the tray, they are thrown out of the granulator with a temperature of 50-70 ˚C.

| Parameter name | A unit of measurement | Value |

| 1. Type of granulator | – | With a rotating matrix |

| 2. Drive type | – | Electric motor |

| 3. The number of revolutions of the matrix | rev/min | 180-280 |

| 4. Productivity | kg/h | 250-500 |

| 5. Installed capacity | kW | 15 |

| 6. Overall dimensions: length, width, height | mm mm mm | 2140 1771 1919 |

| 7. Маss | kg | 410 |

Generalized requirements for raw materials

CHOOSE THE BEST AND BE SURE OF THE RESULT

TELEPHONE NUMBER

MAILING ADDRESS

Ukraine, 36007, Poltava, Zavodska Street, 3