Errors in the operation of granulators

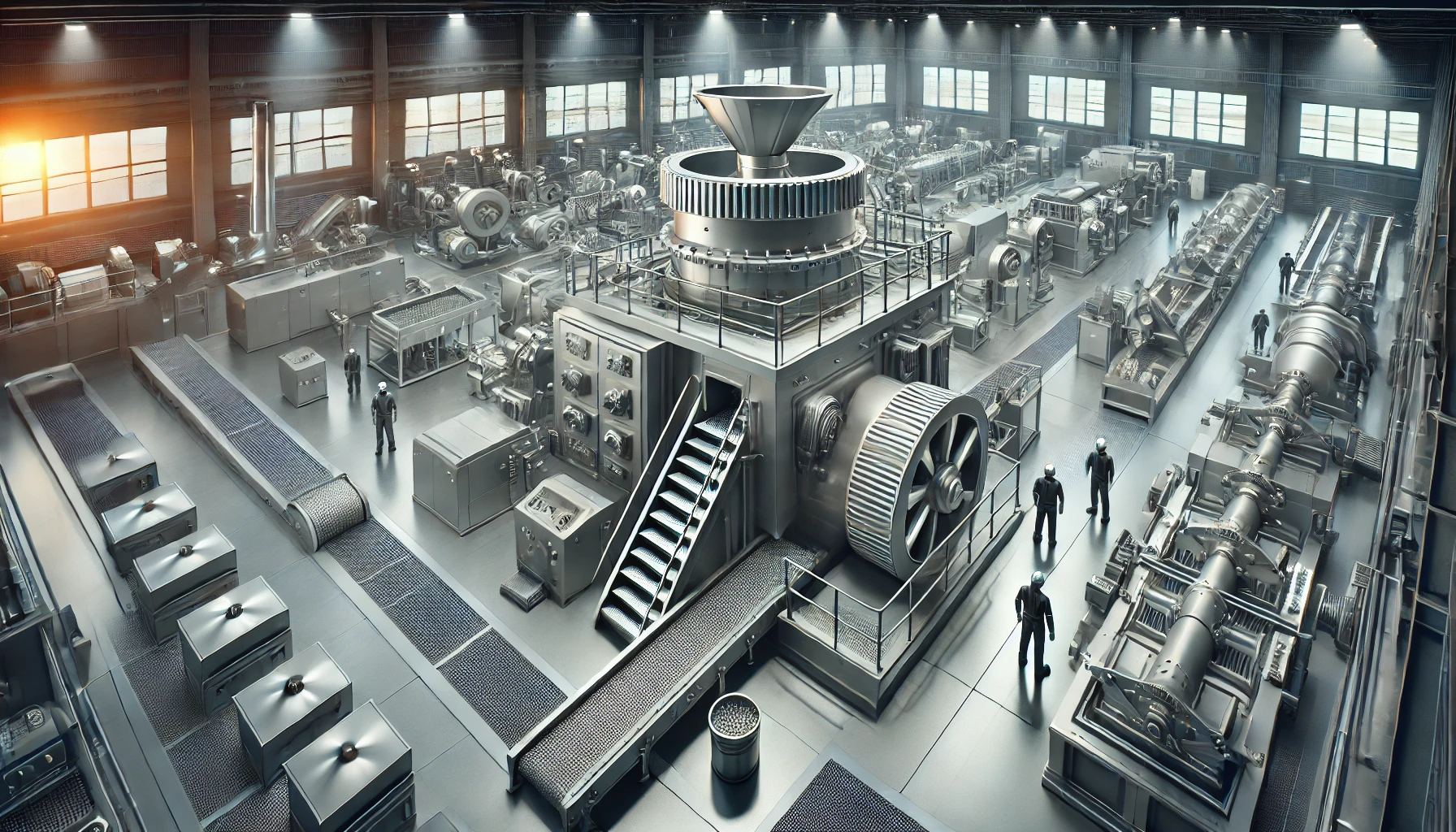

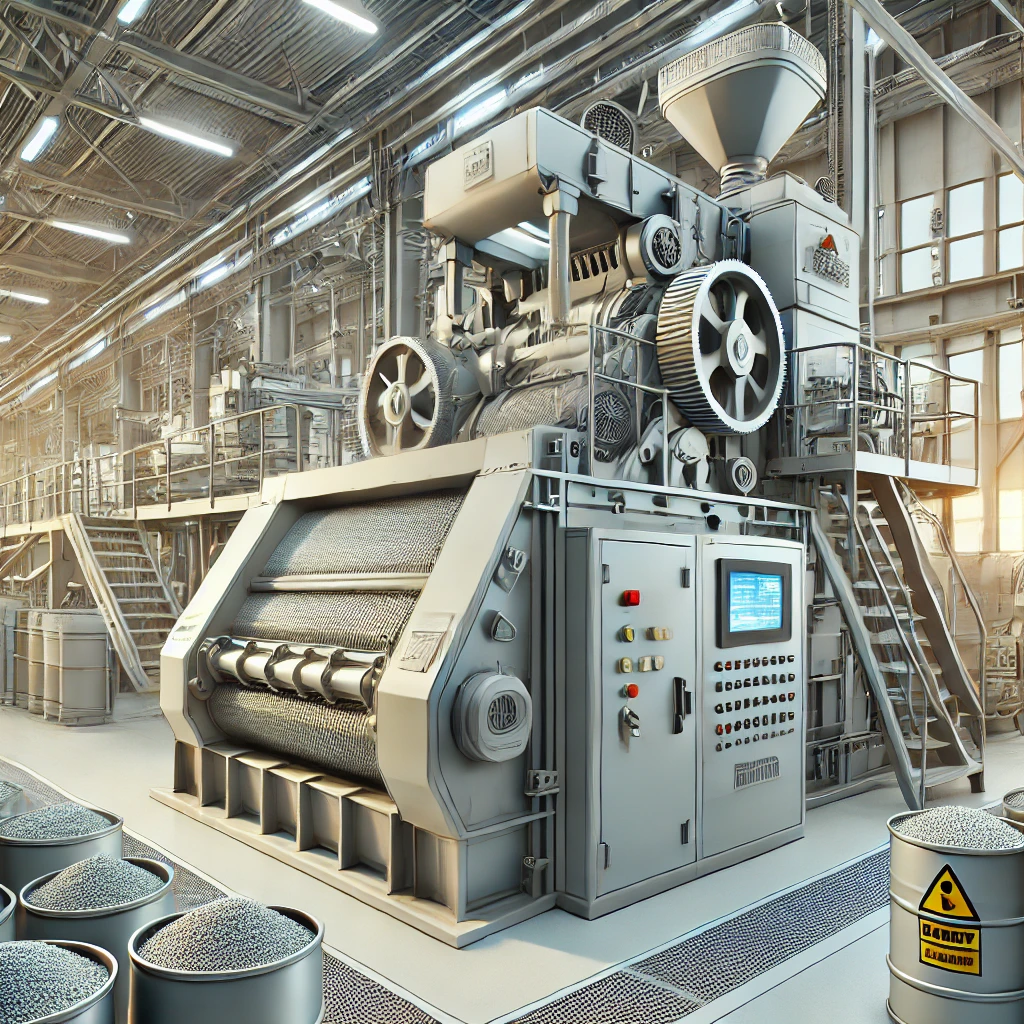

Such equipment as a granulator plays one of the leading roles in numerous industries. Granulation lines help to obtain raw materials in granules, which significantly facilitates its transportation, storage and further use. Of course, this is modern technological equipment, and it brings a lot of benefits, but it is worth remembering that it can lose its effectiveness or fail if you do not operate it correctly. Errors in operation occur quite often, so in order to avoid them, you should fully possess the necessary information and apply it correctly. Knowing about errors is half the way to success, the other half is understanding how to avoid them and ensure a long service life of the equipment.

Typical errors in operation

Errors in operation are a common phenomenon that occur either due to banal lack of information or due to negligence. Both can be corrected, the main thing is to know what to do and how to avoid mistakes.

Top 8 Most Common Mistakes

Raw Material Condition

- The first and one of the common mistakes in the operation of this equipment is the inappropriate humidity of the raw materials. If you plan to produce pellets, you need to pay attention to their humidity. The question arises why, the answer is quite simple. If you do not do this, the pellets you have produced may crumble when interacting with them. Thus, your customers will have questions and a negative experience of interacting with your company, which is a loss of customers and reputation. It is necessary to monitor the appropriate humidity level, because then the raw materials enter the press for fuel briquettes and must go through the following stages of production. Close monitoring will help to avoid unforeseen situations.

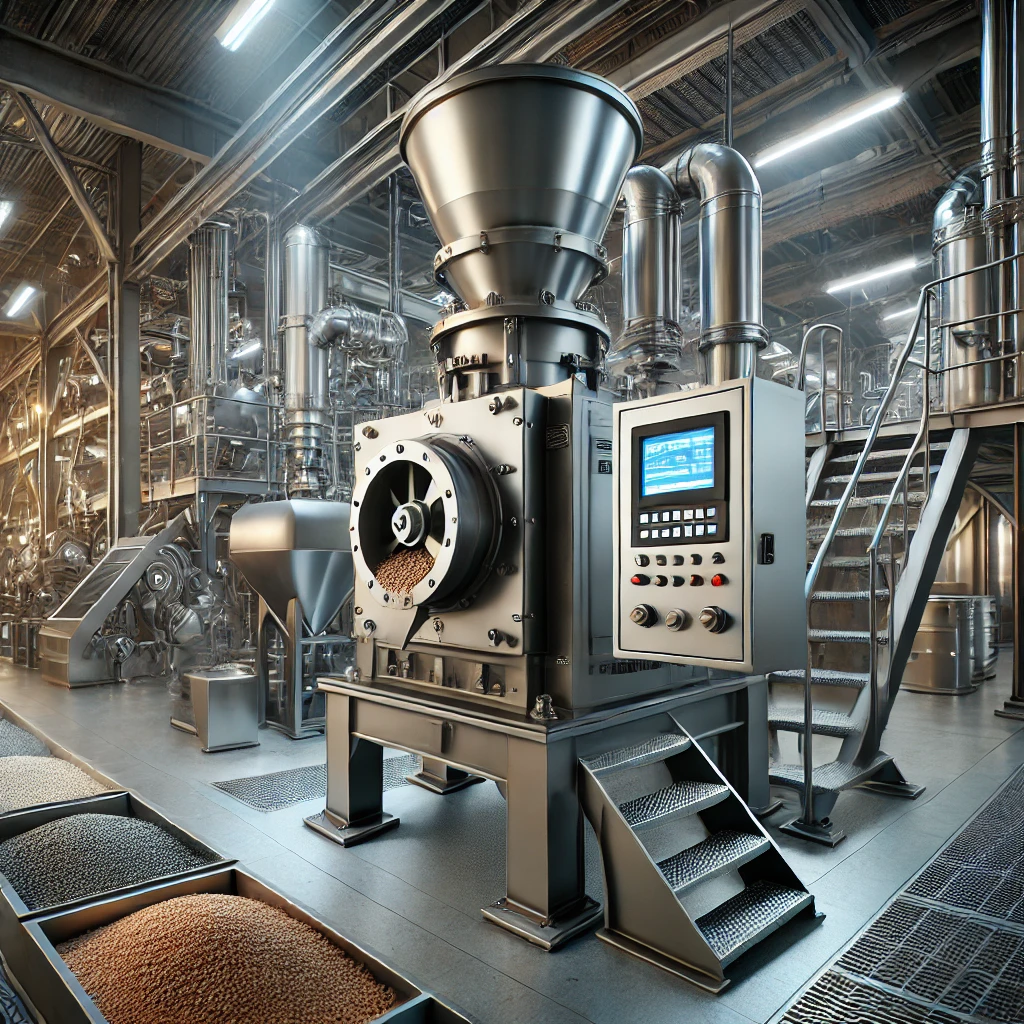

Matrix mismatch

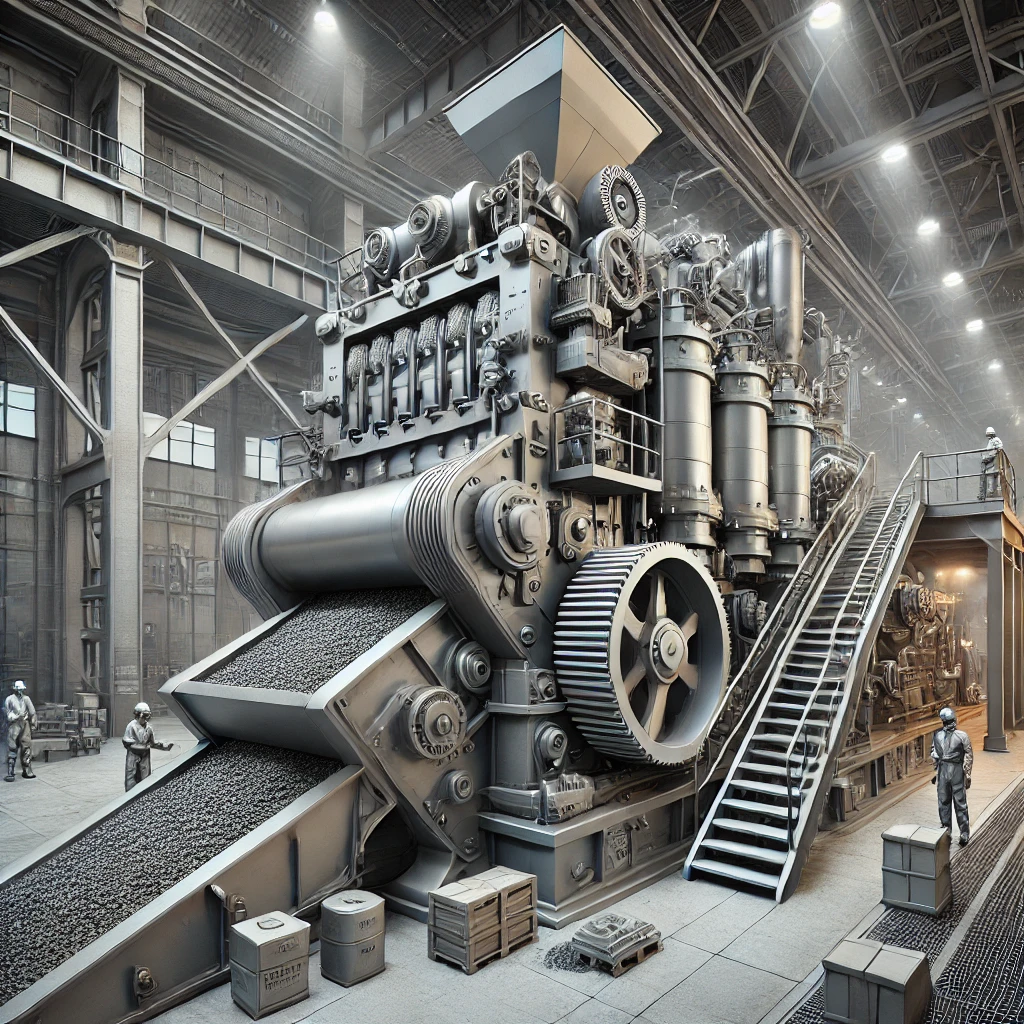

- The next point will be about the mismatch of the matrix to the type of raw material. The granulator matrix is a special device that is used to press the raw material, which at the output has the form of granules. In the granulation process, the correct pressure must be maintained for a specific type of raw material. If at the output you want to get a high-quality granule that does not crumble and keeps its shape, then you need to choose the right spare parts for granulators, in our case it is a matrix. Remember that when choosing a granulator and buying it, you can clarify all the details with the manufacturer. They will definitely suggest the best option and guide you according to your needs.

Incorrect settings

- Make sure that the specialists correctly adjust the gap between the matrix and the rollers, because further work depends on this moment. We are talking about how productive the granulator press will be, how much energy it will consume and how long the matrix and rollers will last you.

Raw material fraction

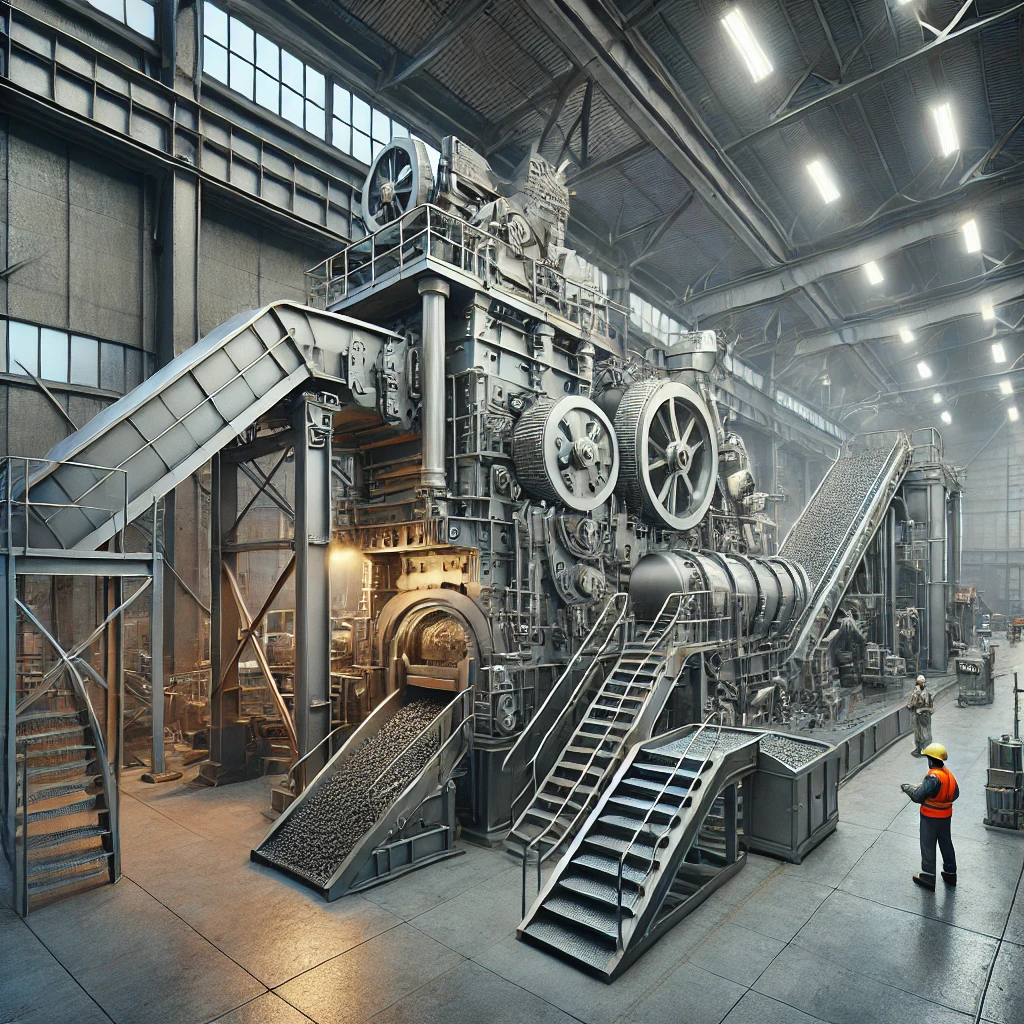

- The raw material fraction occupies an equally important place in this list. In order for the palletizing or granulating process to go as smoothly as possible, you should first prepare the raw material according to its fraction. If the granulator model you have chosen does not have a chopper and raw material of a different fraction gets into it, this can lead to a failure.

Inappropriate equipment power

- The power of the granulator should also be taken into account. This factor is closely related to the raw material you plan to granulate. When choosing equipment, you need to pay attention to the motor for the granulator and its power. It is because the performance of the equipment itself depends on it. You should understand that more powerful options will be able to cope with raw materials for which a weaker version of the equipment is suitable, but if the opposite is true, the granulator can quickly wear out or fail. You should not try to granulate raw materials that are not intended for a certain type of equipment.

Untimely maintenance

- Timely maintenance of the equipment is one of the key factors in the successful operation of not only the granulator, but also any equipment. One of the most common mistakes in the process of using the granulator is untimely maintenance of the device. More specifically, we are talking about untimely lubrication of the components.

Voltage surges

- This point is quite logical and predictable, but still, it can also bring a lot of trouble. We are talking about voltage surges. Yes, ordinary voltage surges can disable equipment. Therefore, to avoid such situations, before starting the equipment, make sure that you have ensured stable voltage. You can also apply surge protection using special equipment.

Foreign particles

- The last point on our list will be the ingress of foreign particles into the granulator. Before loading the raw material, it is worth checking it. Solid wood particles, as well as small foreign objects that were stored in warehouses, can get into the raw material. You need to understand that if you do not forget to follow simple rules. You can significantly extend the life of the equipment and get quality products at the output.

Granulators from PMZ “DENASMASH”

Operation errors are an unpleasant experience, but now that you know the most common ones and how to avoid them, you are one step ahead. Any equipment requires proper operation and proper maintenance. If you follow simple rules, you will be able to use it for a long time without any difficulties. A granulator that is operated correctly will bring you a lot of benefits and financial benefits. If you are looking for a high-quality and wear-resistant granulator, then we suggest you familiarize yourself with our range. You can also buy a briquette press from us to perform the work comprehensively. Contact us at +380(50)3691144, or by email sale@denasmash.com. We will be happy to help you with the choice!

Errors in the operation of granulators