5 reasons to switch to biofuel in the form of briquettes

In modern realities, energy efficiency and environmental friendliness are becoming increasingly relevant and a priority for both private homeowners and enterprises. Undoubtedly, everyone sees the rise in prices for traditional heating methods and their negative impact on the environment. Thus, people are increasingly thinking about finding an alternative. Biofuel is exactly the alternative that is constantly gaining popularity. More specifically, we are talking about fuel briquettes made from renewable resources. Next, we will consider 5 key reasons why you should choose biofuel and what benefits it will bring to you and the environment.

What is biofuel?

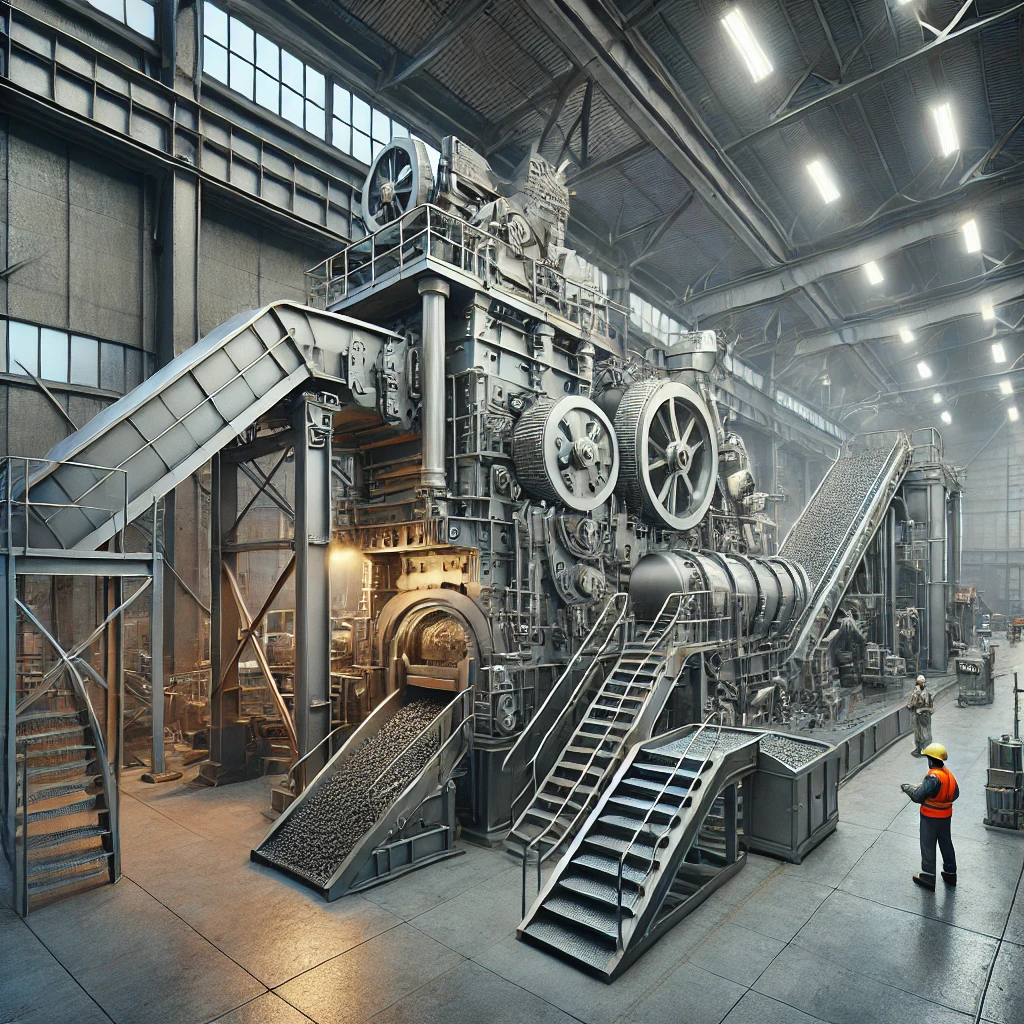

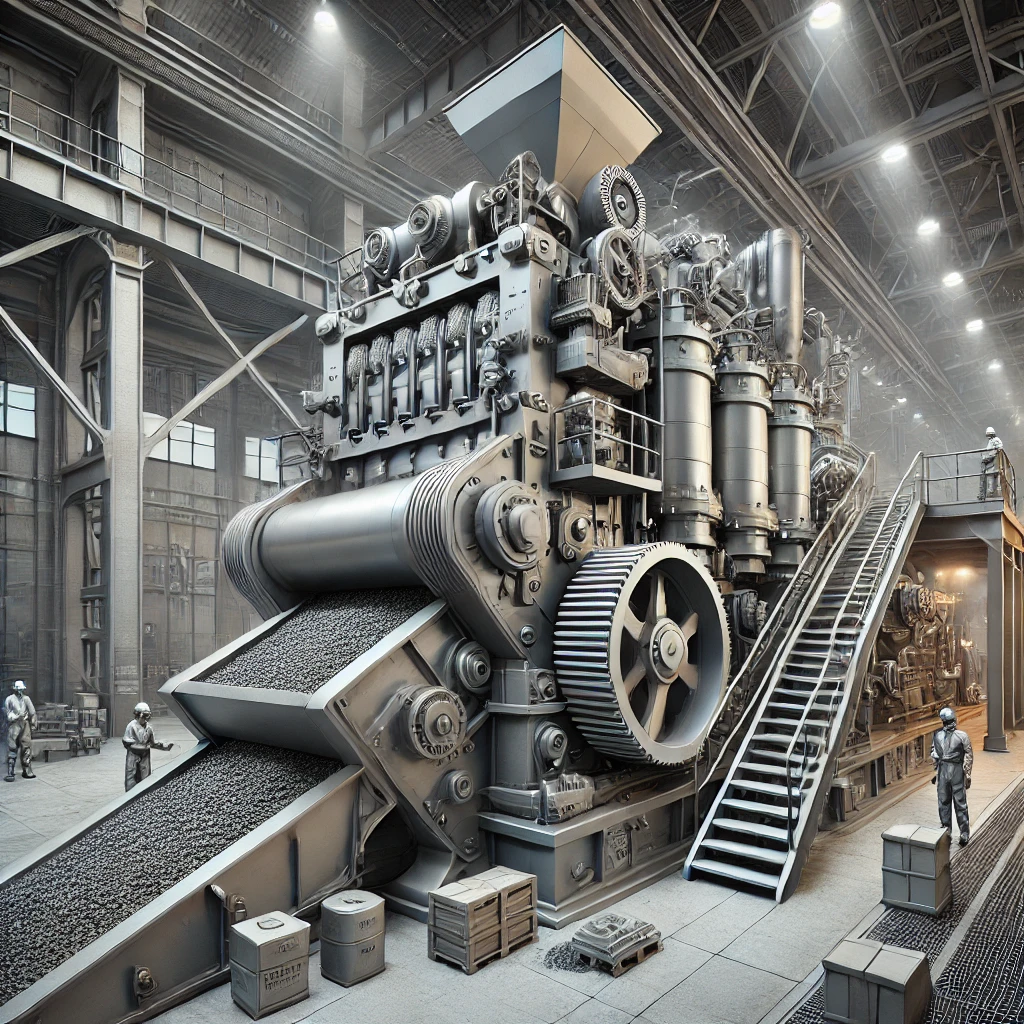

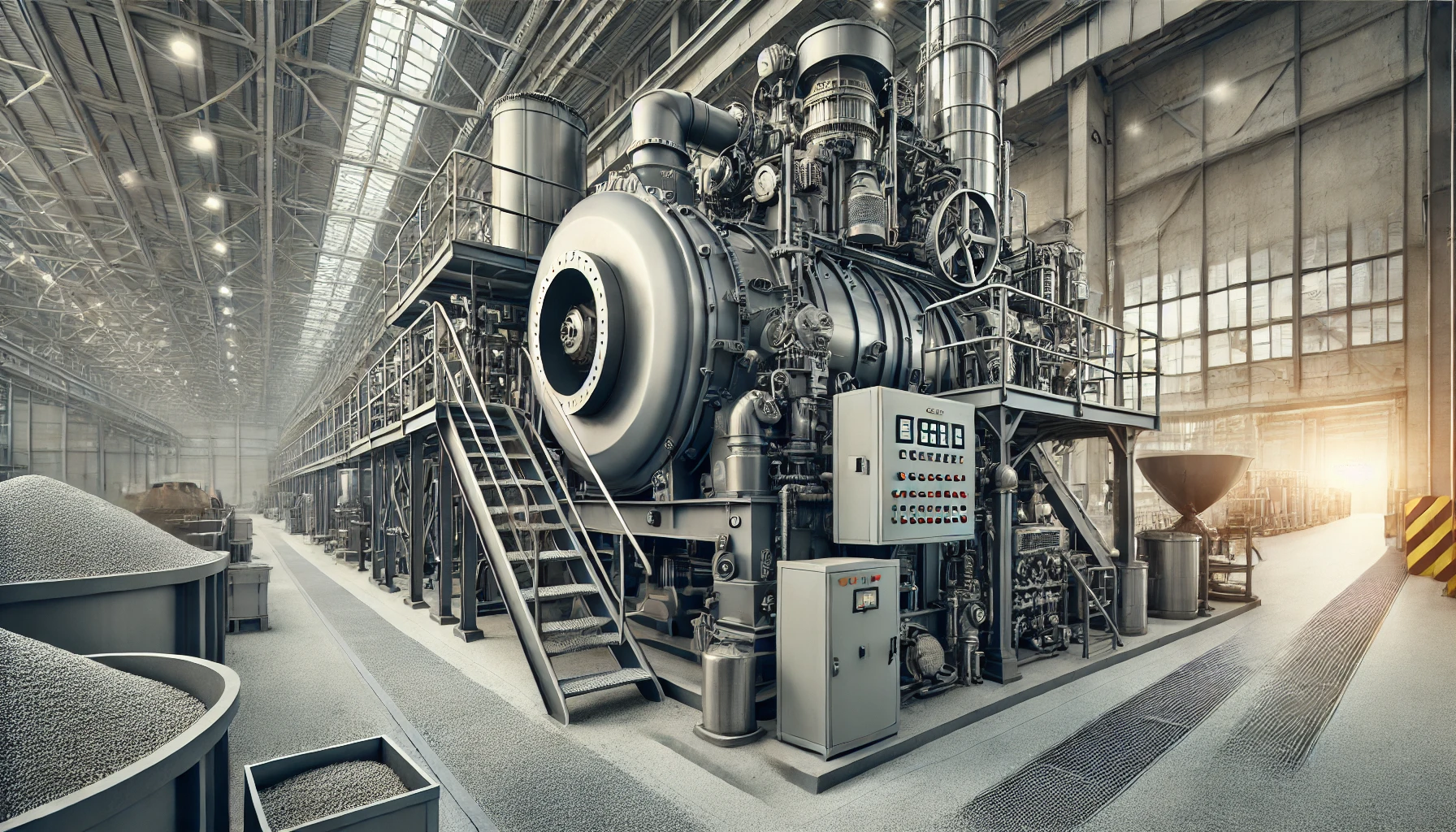

Biofuel is a fuel that is produced from organic materials, namely plants and their residues. We are talking about wood, agricultural crops, waste and similar products. Later, people used this fuel to produce energy. Today, specialists produce it using modern technology, namely equipment known as a briquette press. This process is significantly different from how people extract natural resources such as gas and oil through slow geological processes.

At the moment, biofuels are considered in Ukraine as a significant and promising alternative to traditional fuels. There is an opinion that the production of biofuels in the near future will be beneficial for our economy and will contribute to the development of bioenergy. This path will benefit many entrepreneurs and will allow us to support the ecology of our planet.

5 reasons to switch to biofuels

Economic benefits

- Let’s start with the economic benefits, as biofuels rank among the most cost-effective fuel types in terms of price and efficiency. Manufacturers produce briquettes from waste wood, straw, husks, and other biomass. This process eliminates unnecessary waste and creates a product that provides future benefits. It is worth mentioning that fuel briquettes have a longer burning time compared to classic wood. Thereby providing more heat with less fuel consumption.

Environmentally friendly

- The next, no less important reason why it is worth switching to biofuels is that briquettes are an environmentally friendly and safe product for nature. To make briquettes, you need to move away from agriculture and wood, which reduces the amount of waste. It is also worth noting that producers use biomass, which quickly regenerates, to make briquettes, making this product a great alternative to traditional fuel.

Versatility

- Fuel briquettes are a fairly universal product, as they are suitable for various types of heating equipment. This factor makes them convenient to use. They can be used for various types of boilers. These briquettes are good for industrial facilities, as they are effective for heating large areas, such as production facilities. For private households, this is also a good option, as they can be used to heat a house perfectly.

Transportation

- For many people, ease of transportation is one of the important factors when choosing heating. Briquettes stand out for having a compact shape, which significantly simplifies the process of transporting them. Due to their density and the same shape, they are easy to fold and take up less space compared to firewood. It is important to store briquettes in a dry room to maintain their properties for a long time.

Relative stability

- The last item on our list will be relative stability. The price of this type of fuel is relatively more stable than for gas or oil. It is also worth noting that briquettes are easier to transport to remote regions where access to fuel is limited. Biofuel is a renewable resource, so it is a good choice in the future.

Biofuel production equipment from PMZ “DENASMASH”

From the above, it becomes obvious that biofuel is a good choice in the long term. Switching to biofuel is not only about economic benefits and many advantages for you as an entrepreneur or homeowner, but also about environmental friendliness, stability and conscious consumption and processing of raw materials. If you have long thought about wanting to produce fuel briquettes yourself, then we can help you with this issue. On our website you can find a reliable briquette press, which is distinguished by its durability and quality. Such equipment is undoubtedly a great investment for your enterprise, because you will be able to produce briquettes yourself. You can buy a briquette press by contacting us at +380(50)3691144, by e-mail sale@denasmash.com, or on the company’s website. Our specialists will be happy to help you with the choice and answer all your questions.

5 reasons to switch to biofuel in the form of briquettes