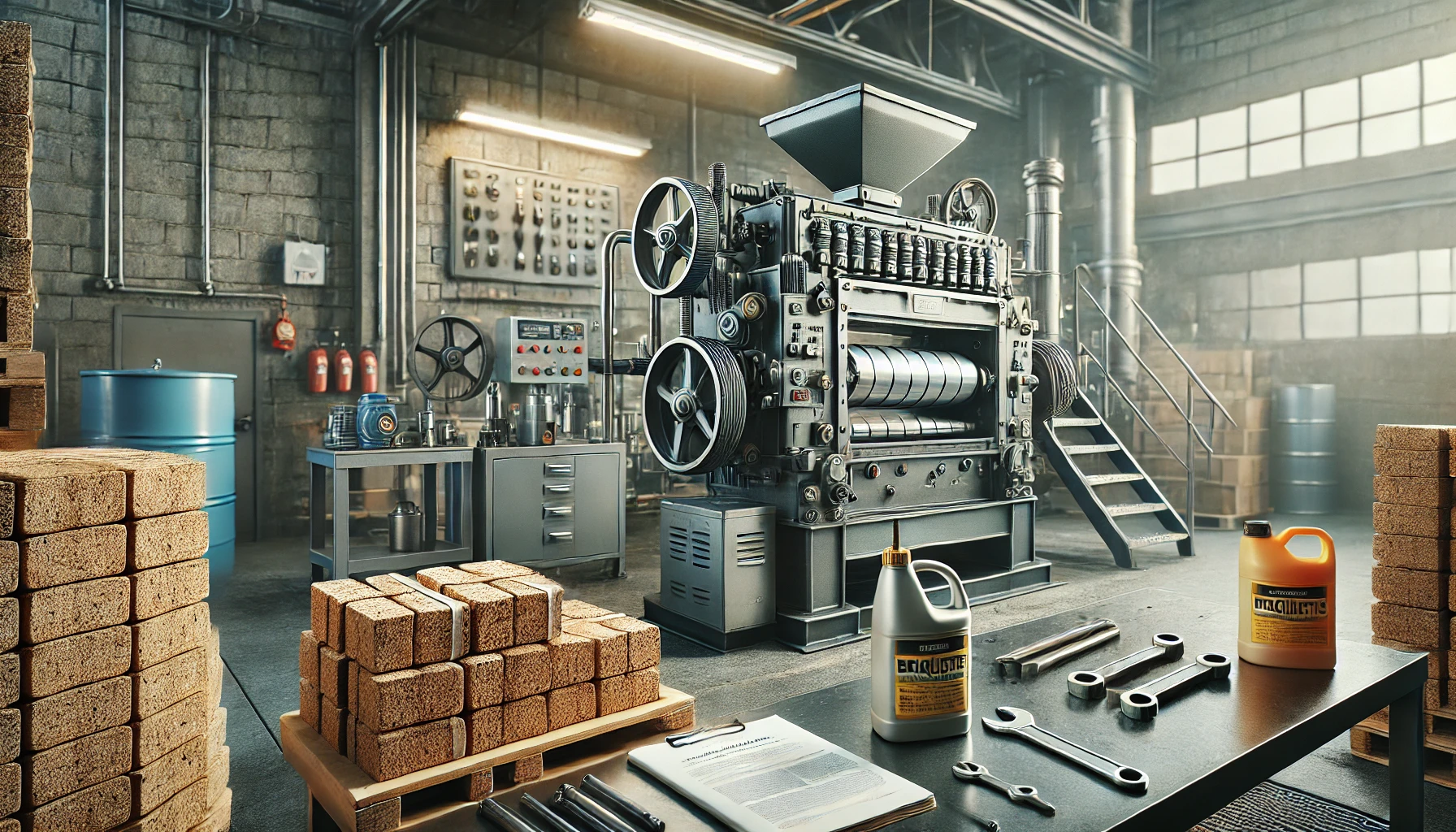

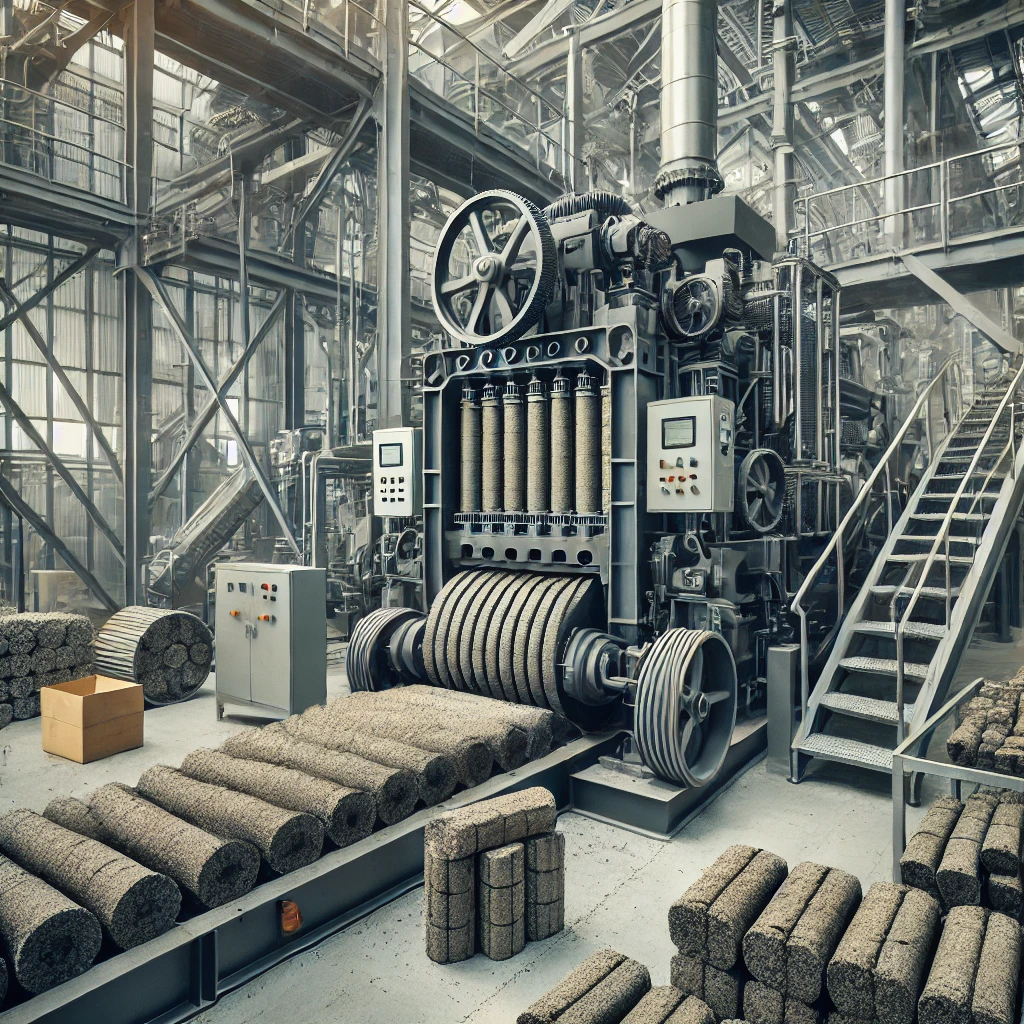

Briquette press maintenance – useful tips

A fuel briquette press is a useful and necessary piece of equipment that helps to process waste into valuable fuel. Of course, every owner of any equipment wants it to last as long as possible and perform its functions properly. As with any equipment, maintenance of the briquette press must be correct so that it can work for a long time and efficiently. You need to follow simple but important rules for operating the equipment. This way you will avoid unnecessary repair costs, extend the service life of the press and ensure stable quality of briquettes. Next, we will talk about key tips that will help you with this.

Press Maintenance – How Does Regular Maintenance Affect the Lifespan of Your Equipment, and What Should You Do?

Regular maintenance is a key factor in ensuring that your press will last and run smoothly. Lack of proper maintenance can lead to major problems that can take a significant amount of time and effort to fix. So let’s take a look at the impact of regular maintenance to better understand its importance.

Avoiding premature wear of parts

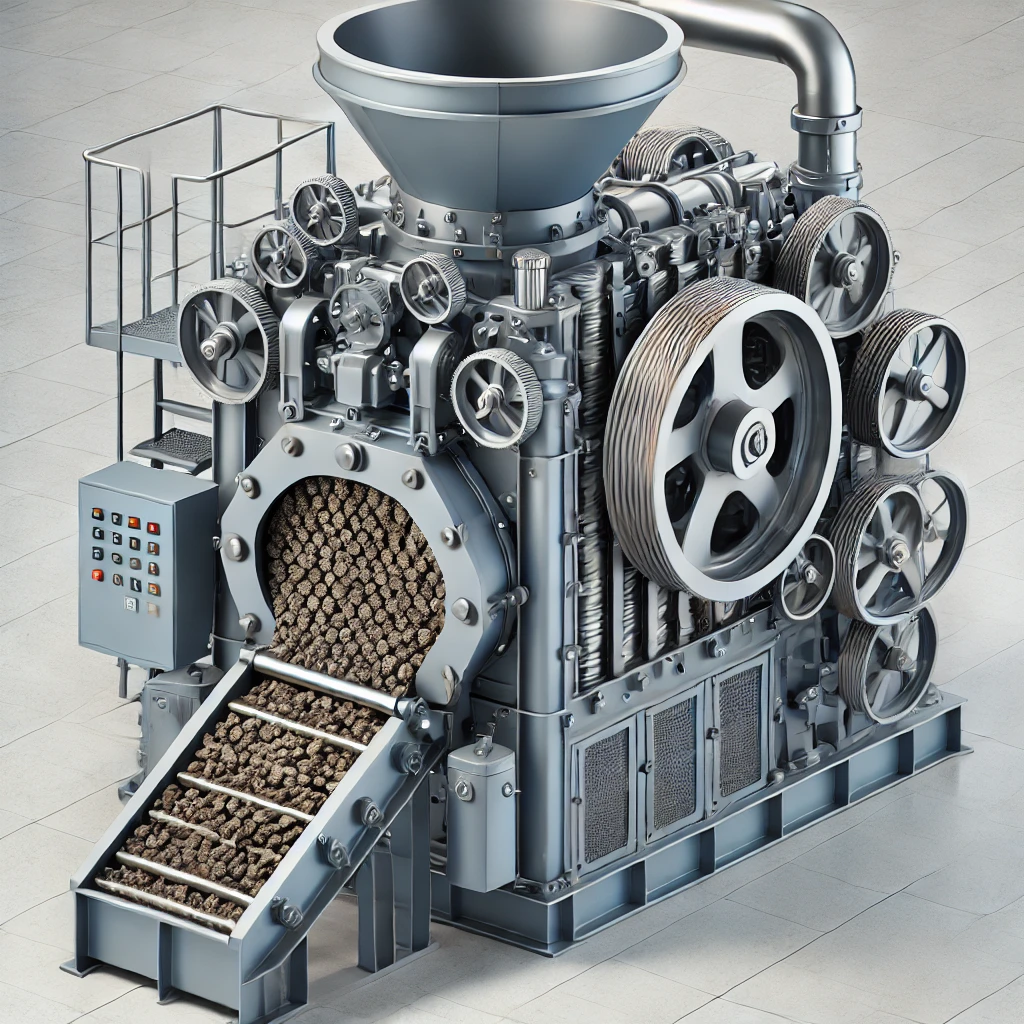

All elements of the press work under heavy load every day. We are talking about matrices, rollers, gears, bearings, shafts and other equipment elements. If you do not clean and lubricate them in time, increased friction will occur, which will lead to rapid wear and breakage.

What to do?

It is worth regularly lubricating and changing consumables. For lubrication, special oils are used, which are available on the market. Also pay attention to extraneous noises and creaking, if you notice uneven operation of the press, or accelerated wear of parts, this is a sign of insufficient lubrication.

Maintaining stable productivity

Dirt, dust and residues of various raw materials can accumulate in the press boat. They can complicate the movement of parts and increase energy consumption. As a result, the productivity and quality of finished briquettes decrease.

What to do?

It is necessary to take care of timely cleaning of the equipment. Clean the briquette press after each use using special auxiliary brushes or other tools. Don’t forget to clean the pressing mechanisms, there are special solvents for this. This way you will avoid possible problems with the equipment and maintain stable work efficiency.

Reducing the risk of unexpected breakdowns

Everyone knows the situation when a necessary thing or equipment breaks down at the most inopportune moment. In the best case, the problem can be solved in a short time and everything stabilizes, in the worst case, the process of solving the problem can take from several hours to several days. In any case, everything is accompanied by stress, nerves and often lost money and opportunities.

What to do?

It is regular technical inspection that prevents unexpected equipment breakdowns before they cause the entire mechanism to stop. Agree, when the entire fuel briquette production line stops, you can suffer serious losses and financial losses, so it is better to closely monitor the condition of the equipment.

Preventing overheating of fuel briquette production equipment

Overheating is one of the most common reasons why equipment can fail, so you need to monitor this moment.

What to do?

It is necessary to regularly monitor the level of oil and the cleanliness of the cooling elements. If the temperature exceeds the permissible limits, it will negatively affect the engine and other parts of the equipment. If you notice that the equipment body is too hot or smell burning, this indicates that the press is overheating.

Press maintenance – reducing repair costs

Untimely maintenance often leads to major repairs, or even complete replacement of equipment. This can be a big problem, because when production is established and there are supply agreements, untimely breakdown of equipment causes difficulties.

What to do?

Scheduled maintenance is something that should not be neglected. Regularly replace parts, monitor the temperature of the press, clean the equipment and do not forget about maintenance. As a result, your briquette press will serve you for a long time and reliably.

Briquette press maintenance with PMZ “DENASMASH”

Regular maintenance of a briquette press not only ensures its durability, but also reduces many risks associated with operation and productivity. By following simple rules, you can be sure that your equipment will not stop at the most inopportune moment. By investing time in proper and timely maintenance, you will be one step ahead, as you will avoid numerous breakdowns.

You can buy a briquette press that will meet the highest quality standards and will work properly on our website. Contact us at +380(50)3691144, or by email sale@denasmash.com. Our specialists will help you with the choice and will be happy to answer all your questions.

Briquette press maintenance – useful tips