Granulators – what are they and how do they work?

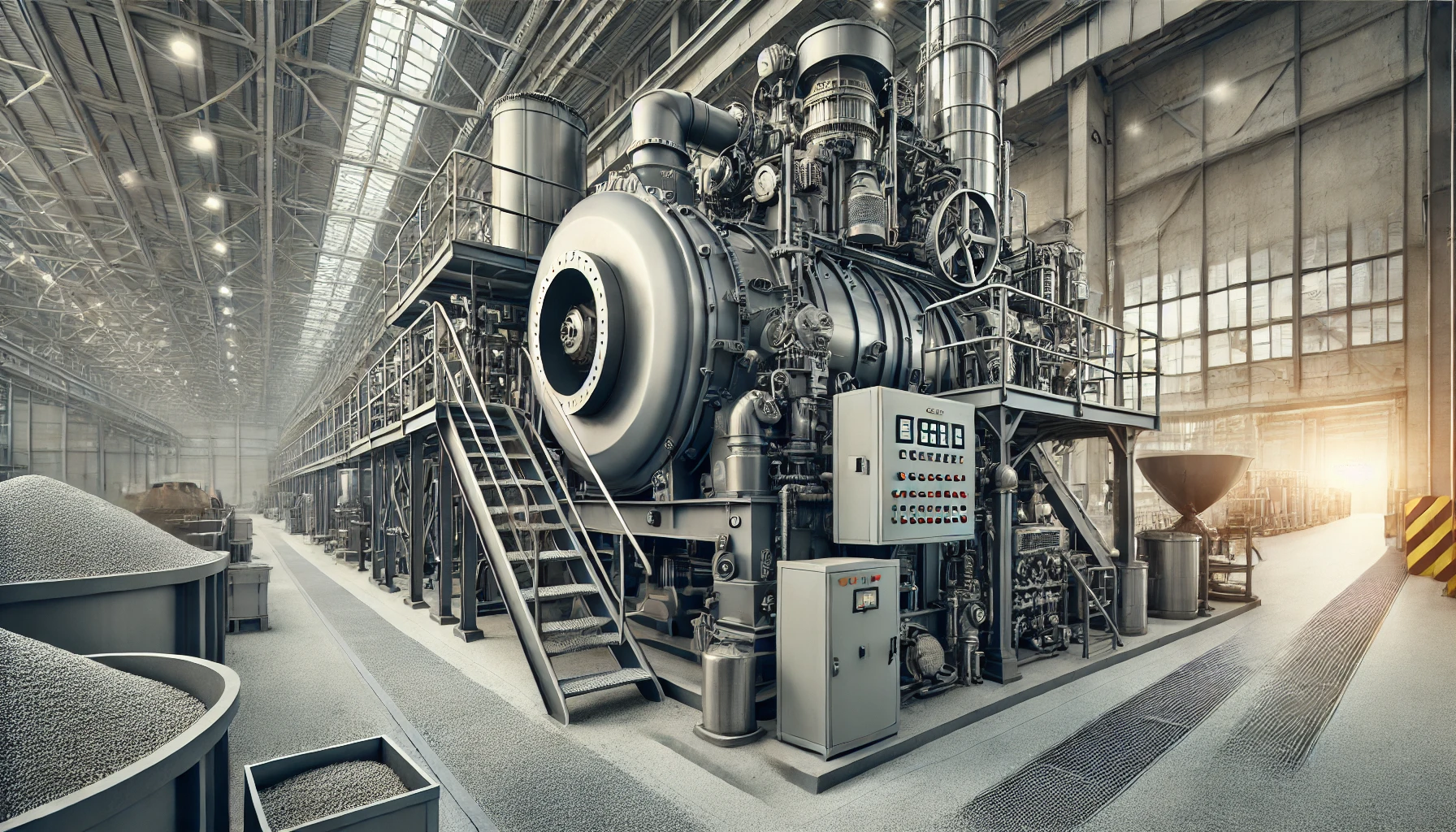

Granulators are special equipment that converts biomass into small granules by crushing and pressing it. Thus, at the output we get a product that can be used for various purposes, depending on the needs of the consumer. Granulated products are easy to transport and store, which adds demand and relevance to this equipment.

Granulators – application areas

- Granulators are widely used in the food industry. They help in the production of compound feed for various animals, as well as in the creation of pellets from feed crops and agricultural waste.

- Plastic granulation is quite common in industry. This equipment allows you to convert plastic waste into small pellets. They come in different sizes and configurations. We are talking about conventional granulators, granulators with a built-in grinder, and granulators for heavy-duty conditions.

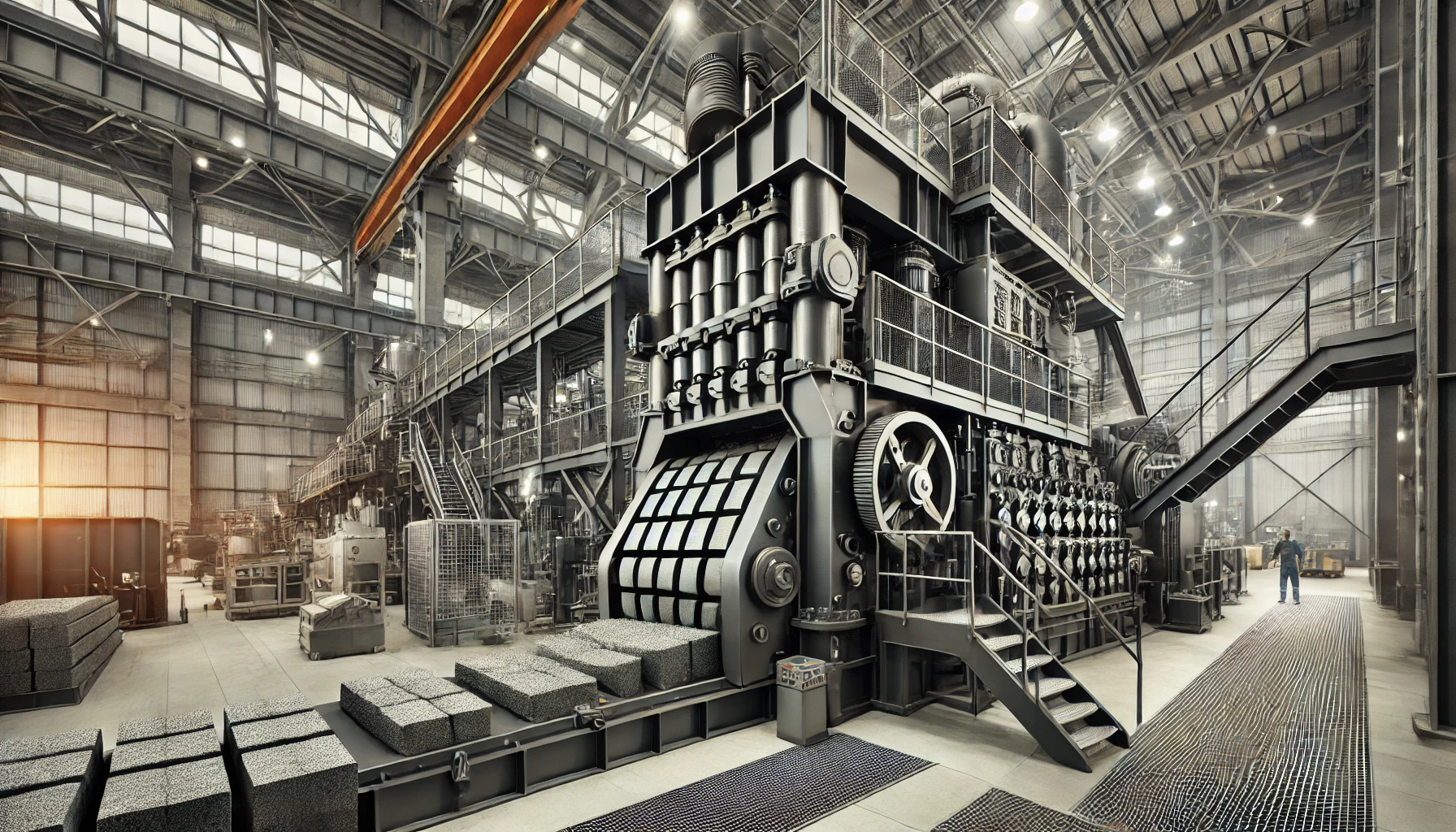

- Metal granulators are used to process metal waste and convert it into pellets. They effectively grind such metal waste as copper, brass, aluminum and stainless steel.

- In the chemical industry, granulators are used to process chemical powders, produce granular chemical fertilizers, plant protection products and other chemical fertilizers.

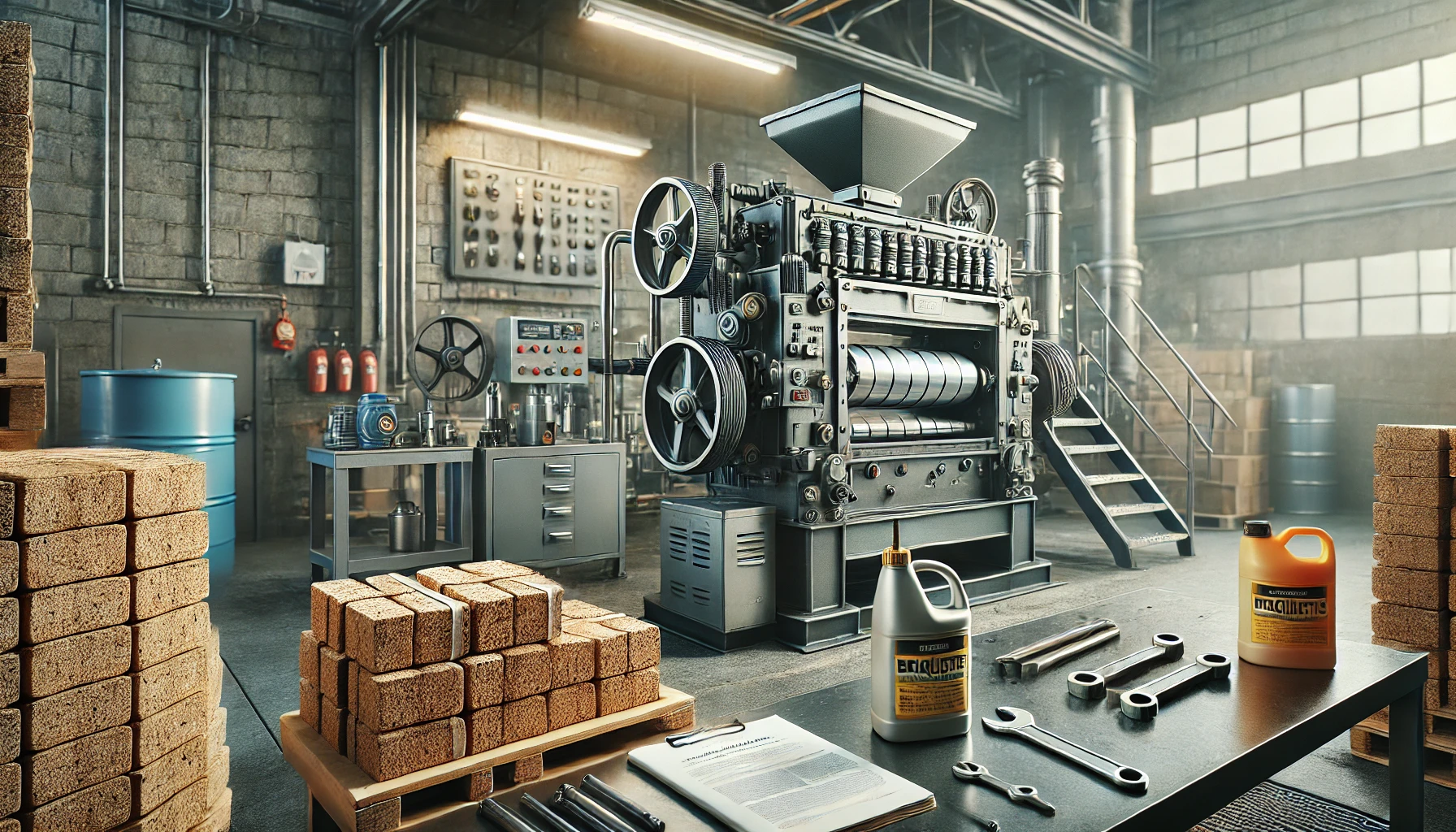

- It is worth mentioning the woodworking industry, because it is thanks to granulators that special fuel pellets can be produced. For example, pellets from sawdust, chips and other wood waste.

Granulators are widely used in each of the above-mentioned industries, as they are an indispensable tool in creating the desired products.

Types of granulators

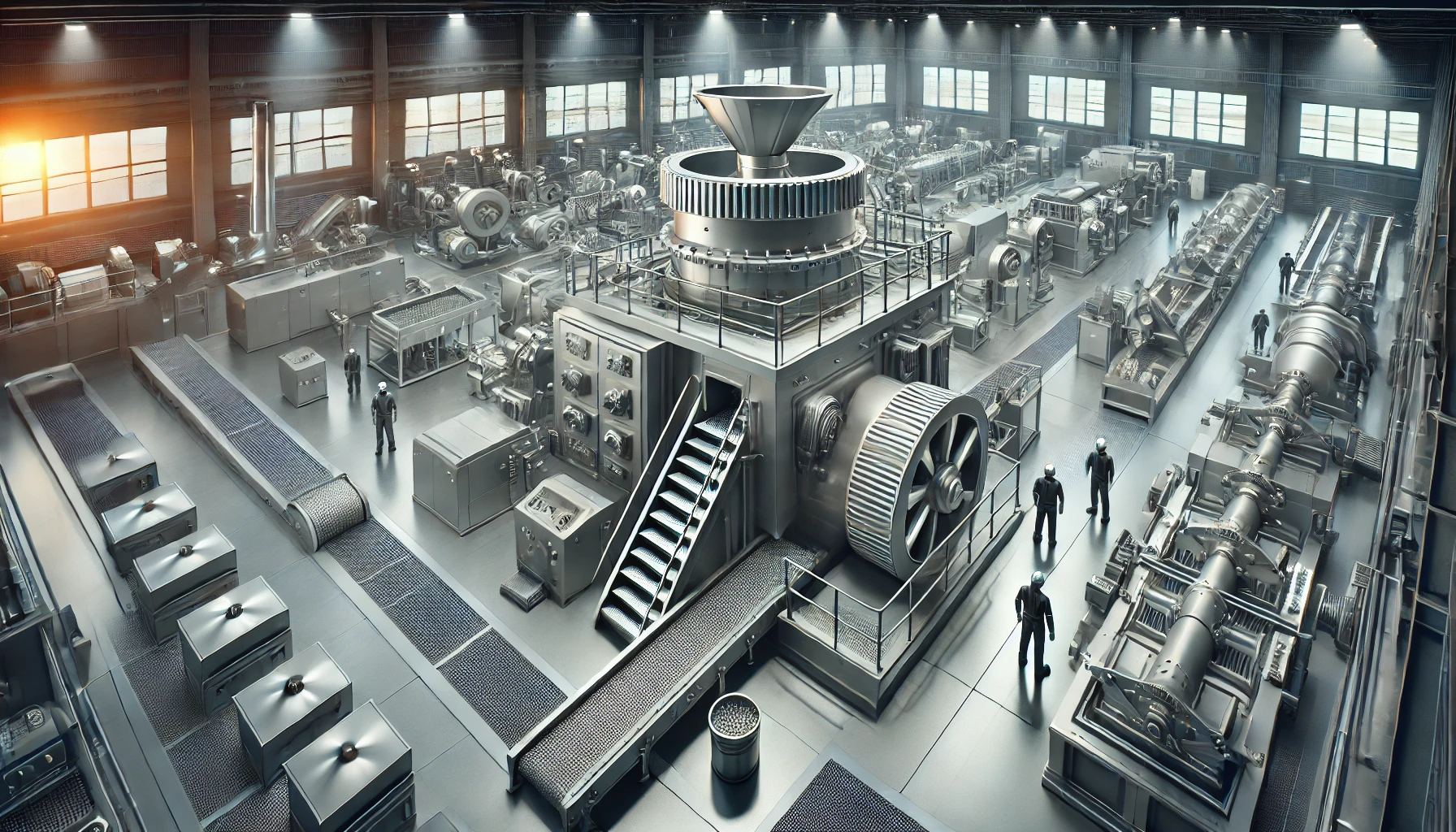

Granulators come in different types, so when choosing them, it is important to understand for what purpose you are choosing the equipment. Our company’s assortment has a wide selection, so everyone can choose the right option for themselves.

- Granulator OGM-1.5M up to 1.5 t/h

- Granulator B6DGV-M up to 2.2 t/h

- Spare parts for granulators OGM-1.5 and B6DGV

- Granulation line from 1.5 t/h

- Sonic granulator

- Press granulator GR-1

All the above models do their job perfectly. Due to the fact that the enterprise operates in accordance with advanced standards, our products are highly efficient and easy to operate. All granulators are made of high-quality materials, so they will serve you reliably for more than one year.

Advantages of using granulators

- This equipment has numerous advantages and has found application in numerous industries. So let’s consider its key advantages.

- The first and most significant advantage is the effective use of the granulator in the processing of raw materials and biomaterials. By choosing the path of waste and biomaterial conversion, companies and enterprises reduce the amount of the same waste. They save costs and reduce the negative impact on the environment.

- The ability to obtain the necessary product in granules significantly facilitates its storage and transportation. The need for additional processing stages is also reduced.

- The granulator is fairly versatile equipment. They can accommodate different materials and allow you to change the shape and size of the granules. Thus, this factor serves the reason that they are used in various industries.

- A modern granulator is energy-efficient equipment. It does not consume too much energy and, at the same time, does its job perfectly.

Poltava Mechanical Plant “DENASMASH”

A granulator is an indispensable assistant in many industries, which facilitates the granulation process and makes it automated. When choosing a granulator, consider your needs and be sure that this equipment will bring you a lot of benefits. We would like to note that our company has been manufacturing high-quality and reliable granulators for more than one year. A wide selection is available on our website. We also provide various services, such as metalworking, milling, heat treatment and others. Contact us at a convenient time for you at +380 (50) 369 11 44 or sale@denasmash.com. We will provide answers to all your questions. By choosing DENASMASH LLC, you choose high-quality, reliable and durable products.

Granulators – what are they and how do they work?