Why is it worth investing in modern briquette presses?

Each of us has noticed that the modern world is increasingly striving for environmental friendliness and preservation of natural resources. More and more often frequently, we see solar panels on houses, windmills in the fields and other measures aimed at obtaining energy in an environmentally friendly way. The cost of living is rising rapidly, and environmental problems are becoming increasingly widespread. The search for alternative energy sources is becoming a necessity that humanity is striving to support it. In this article we want to talk about one of the a highly promising solution, namely, modern briquette presses.

Briquettes are an environmentally friendly, efficient and economically profitable type of fuel. By choosing the path of investment in modern equipment for the production of fuel briquettes, you choose the opportunity not only to get a stable profit, but also to support the ecology of our planet, which is very important! So let’s move on to the main question – why is it worth investing in modern briquette presses?

What is a briquette press, and what is its role in the production of fuel briquettes?

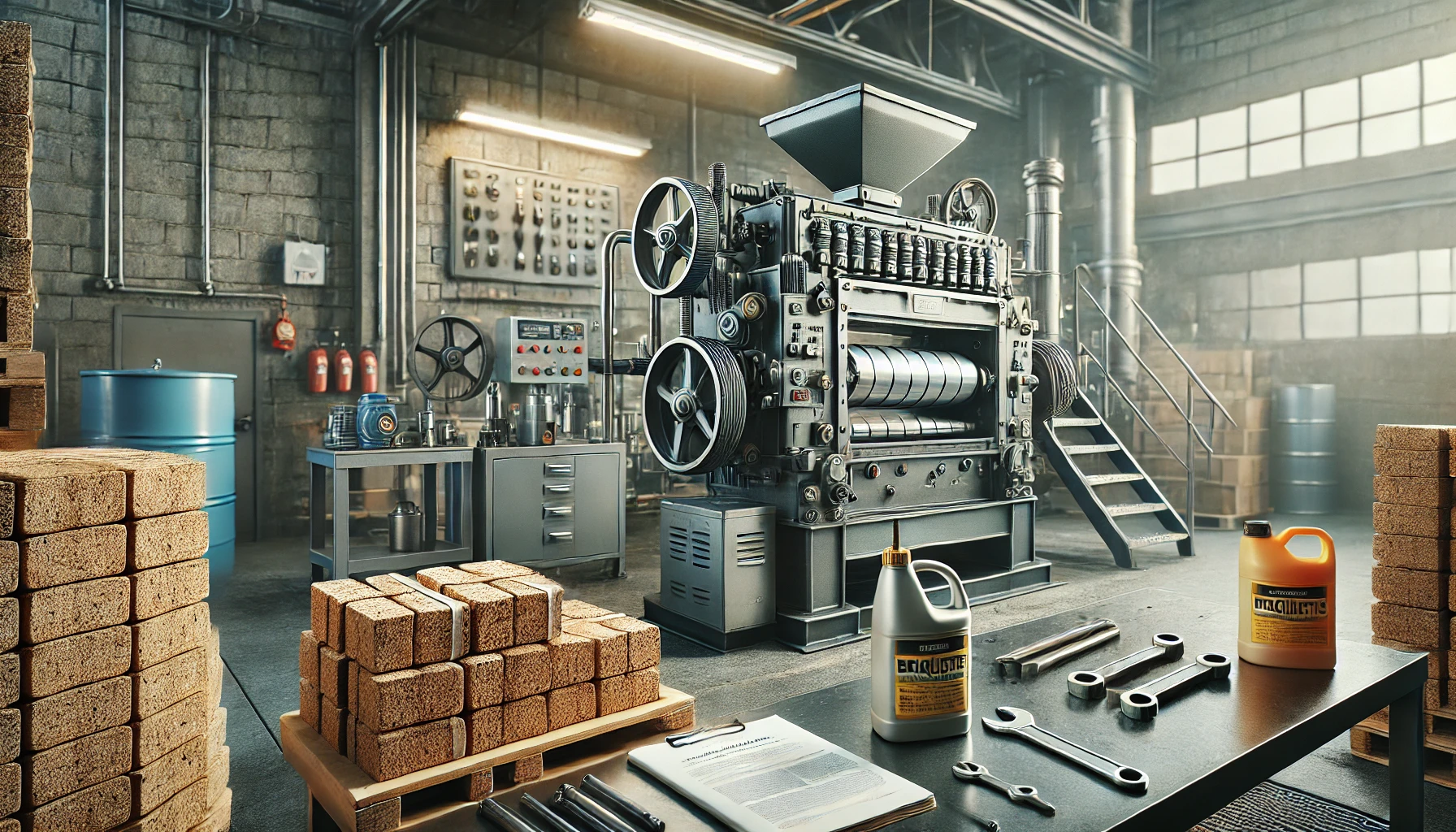

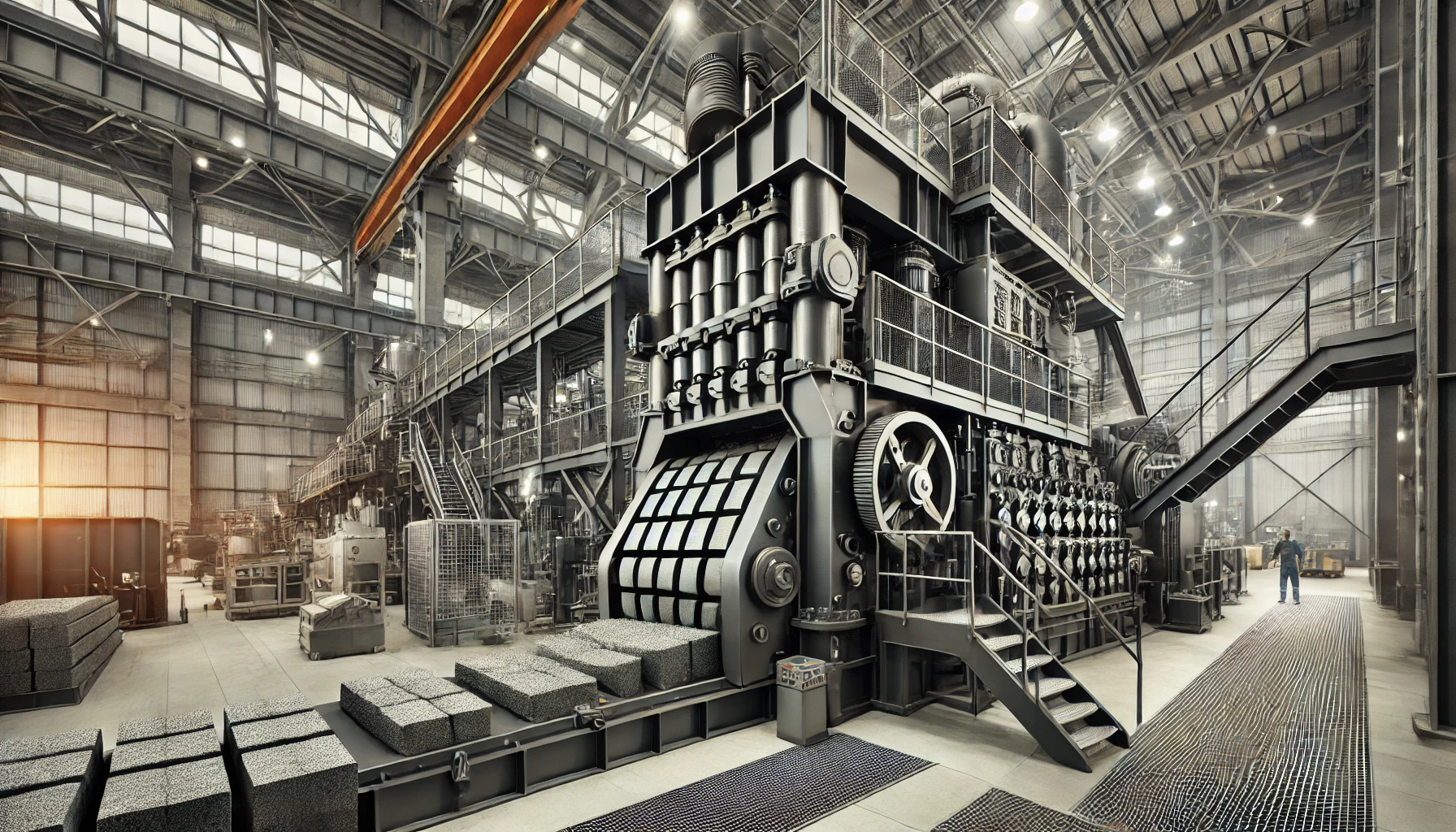

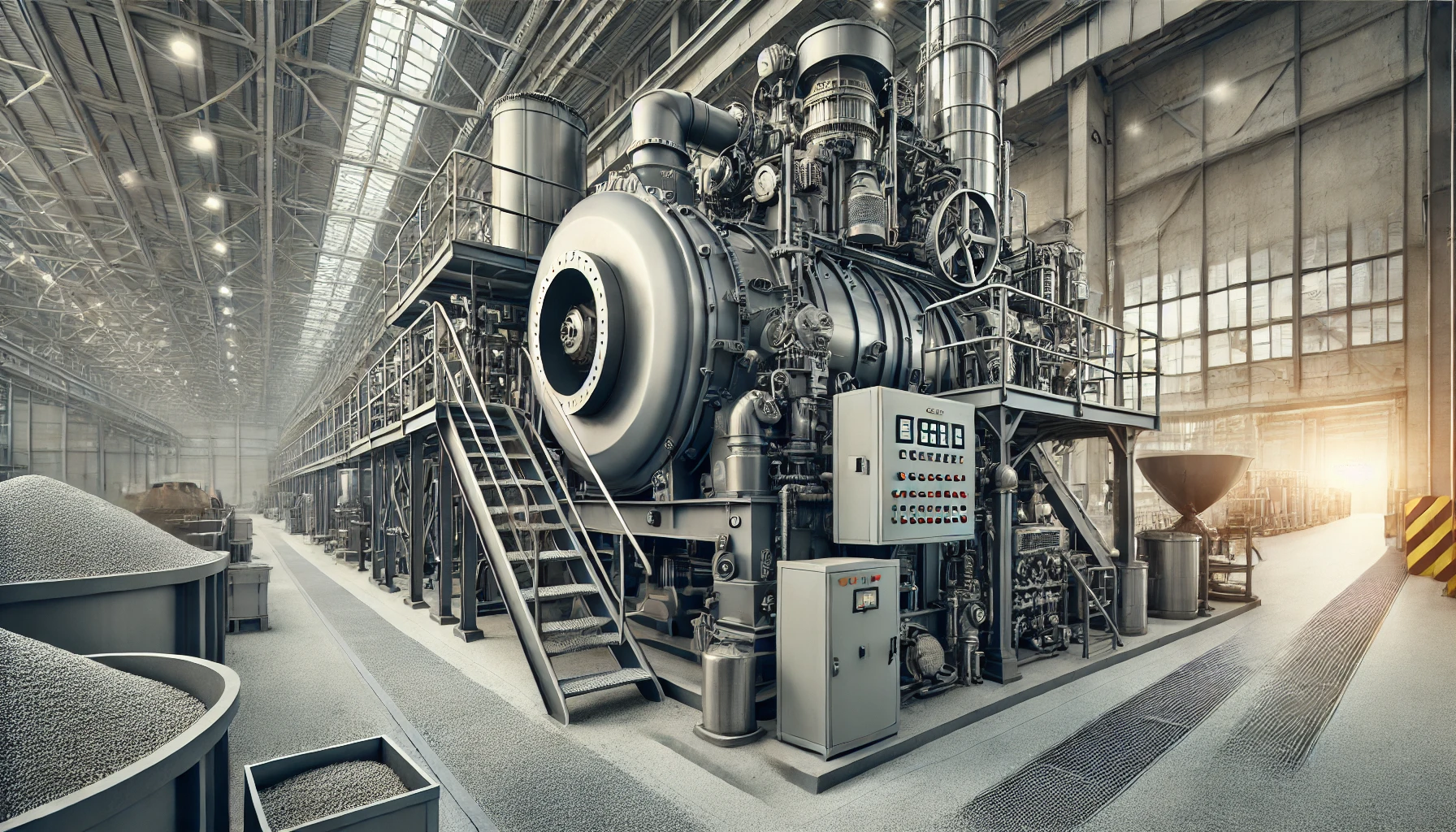

A fuel briquette press is a specialized machine that processes various types of biomass or industrial waste into solid fuel briquettes. It operates by compressing the crushed raw materials under high pressure, usually without adding any chemicals. As a result, fuel briquettes are formed that have high density and energy efficiency.

Modern briquette presses – types

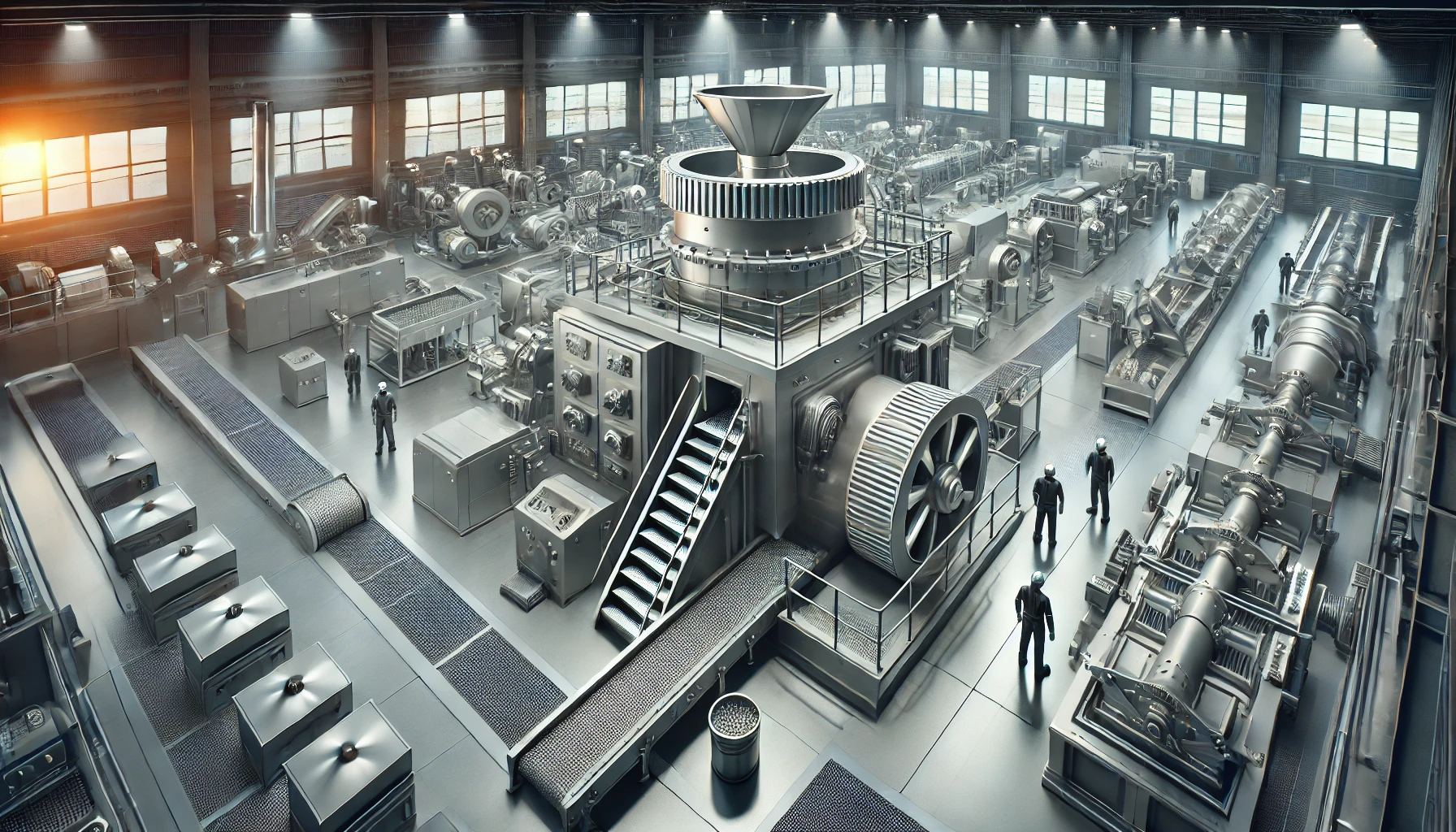

Modern equipment is quite diverse. Accordingly – your choice is not limited, and everyone will be able to find for themselves something that will fully meet the needs of production. There are several types of briquette equipment, namely:

Hydraulic presses are a special machine that works with the help of a hydraulic cylinder, which creates a large compressive force. It may work a little slower, but in return you will get briquettes with high density.

An impact-mechanical press operates using a flywheel and a mechanical plunger, ensuring high productivity and pressing speed. Its operating principle can be likened to a traditional stamping machine, namely, simplicity of design, high efficiency of transfer and speed of response.

Extrusion presses are a special machine that forms briquettes by feeding heated raw materials through a special matrix, which in turn contributes to a very strong and dense product at the output.

Among these three options, hydraulic briquette presses are the most popular. This is due to the fact that they are able to press wood, biomass, aluminum and metal. It can be concluded that processing solid materials is not a challenge for this technology. The other two presses are also widely used, so when choosing, you need to consider only your request.

The Role of Briquette Presses in Fuel Briquette Production

A fuel briquette production line plays a key role in their creation. So let’s look at a number of specific factors that will help you make sure of this.

Factors

Recycling and disposal of waste

- It is obvious to everyone that one of the main functions of briquette equipment is the conversion of waste wood, agricultural biomass, paper and other materials into compact fuel briquettes. Thus, you have the opportunity to reduce the amount of waste in production. Another significant advantage is that people can use previously unsuitable raw materials, or those with low energy value, with the help of a press. And the last significant advantage is that you minimize the costs of transportation and disposal of waste.

High-quality fuel product

- Modern presses are reliable and high-quality equipment that can provide high density briquettes, which are subsequently convenient to store and easy to transport. You get a product that has a high calorific value. Due to their dense structure, briquettes can burn longer and are able to emit more heat. If, for example, we compare them with wood, we can note that briquettes have a lower moisture content, which is why they burn better. Another important factor is that briquettes leave much less ash, thanks to high-quality pressing.

Production automation

- Today, modern briquette lines are able to operate in automatic or semi-automatic mode. This, in turn, allows you to increase production productivity and ensure stable quality of the final product. Of course, the equipment requires regular maintenance and control, but if you follow all the recommendations, the press for processing agricultural waste will serve you well.

Environmental friendliness

- Although environmental friendliness is listed last, it is actually one of the most important factors. It is the briquette equipment that helps to reduce the environmental load on our environment. To create briquettes, you use renewable resources, which is very important and right. CO2 emissions into the atmosphere are reduced when compared to coal and firewood.

Invest in modern briquette presses together with PMZ “DENASMASH”

Investing in modern briquette presses is undoubtedly a good decision that will bring you many benefits. This is not only a step towards business development, but also a strategically important decision that will lead to economic benefits and support the ecology of our planet. The demand for environmentally friendly fuel is growing, so we advise you to pay attention to our briquette presses. You can buy a briquette press that meets all standards on our website. Contact us at +380(50)3691144, or by email at sale@denasmash.com. We are happy to answer any of your questions!

Why is it worth investing in modern briquette presses?